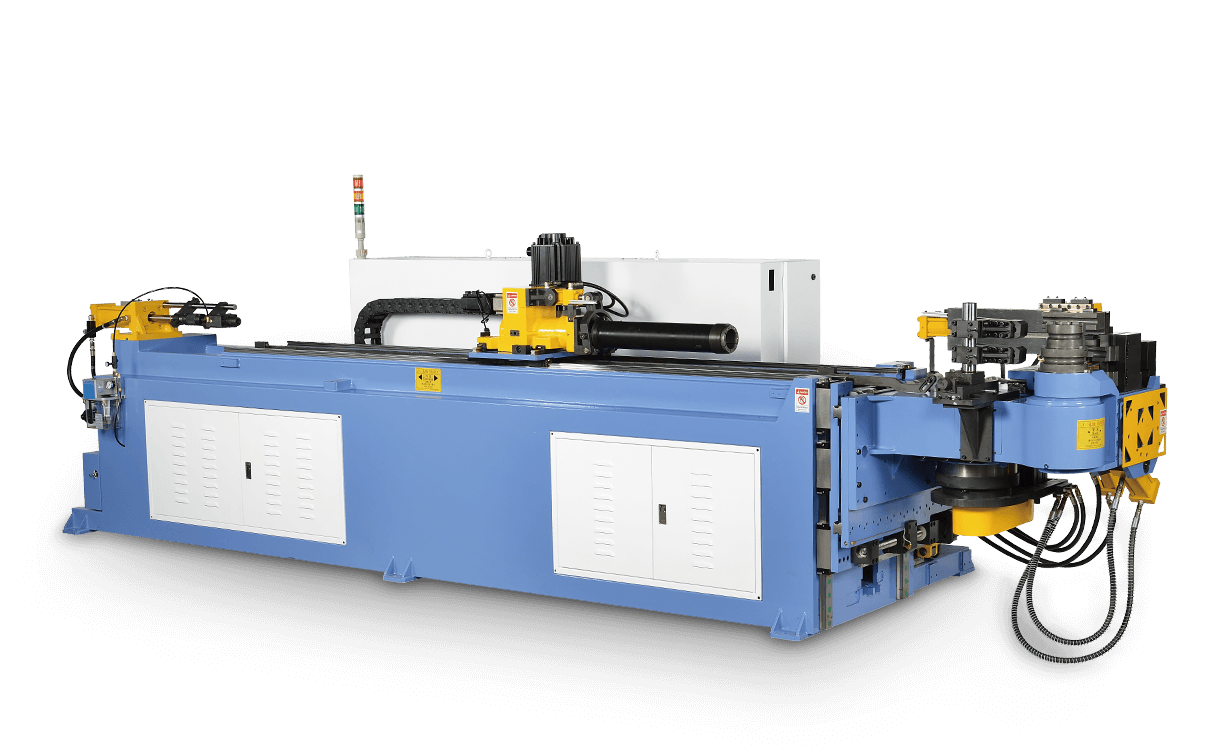

HC-650R3-NSM

Features

Mechanical Design

- Machine’s design is based on dynamic mechanical analysis to offer reliable performance.

- Compact bend head & arm minimize the possible interferences.

- Climbing clamp design enables sufficient space to execute bending efficiently.

- Quick tooling changeover shortens set up time and comforts users.

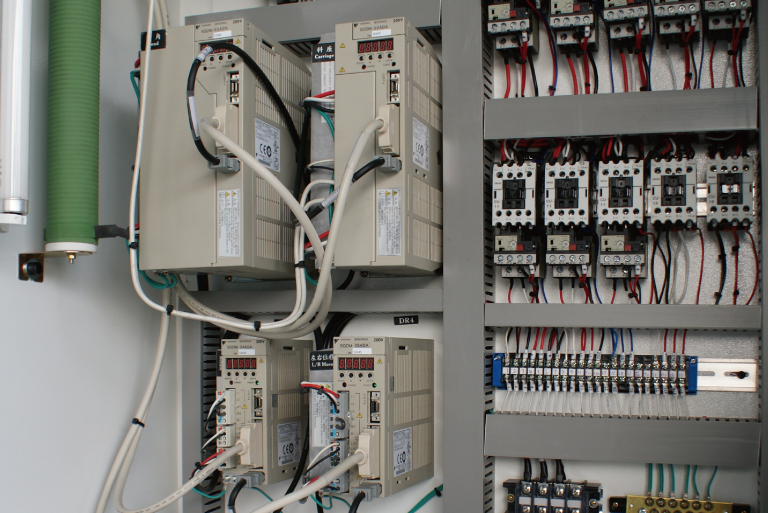

- Individual electrical cabinet is mounted separately from the machine to prevent the affection of vibration.

- Motions driven by all electric-servo motors assure the high accuracy & repetitive performance.

- Auto-Tooling Positioning Function :Clamp/Pressure die are positioned automatically via smart torque control.

- High Stability : All electric-servo control without oil temperature problem.

- Low Noise

- Low Pollution

specification

| Spec / Model | HC-650R3-NSM | |

|---|---|---|

| Max. Tube O.D. & W.T. (O.D. x t) | Mild Steel (mm) | ø63.5 x 3.0 |

| Stainless Steel (mm) | ø50.8 x 2.0 | |

| Rectangle Pipe (mm) | □50.0 x 2.5 | |

| Max. Draw Bending Radius (Max. R)(mm) | 250 | |

| Push Bending Radius | *Min. (mm) | 7D~10D |

| Max. (mm) | ∞ | |

| Max. Bending Angle (degree) | 200° | |

| Max. Effective Distance of Mandrel (mm) | 3000 mm | |

| Electric-Servo Speed | Feeding (mm/sec) | 1000 mm |

| Rotation (degree/sec) | 200° | |

| Bending (degree/sec) | 100° | |

| Electric-Servo Accuracy | Feeding (mm) | 0.05 mm |

| Rotation (degree) | 0.05° | |

| Bending (degree) | 0.05° | |

| Total Power (HP) | 56 HP | |

| Machine Size (L x W x H)(mm) | 6000 x 1700 x 1700 mm | |

| Machine Weight (kgs) | 5,200 kgs | |

Remarks:*Min. push bending radius(mm) : it’s subject to tube O.D, W.T, tube material..etc.