FTH6130

Competetive priced CNC Turning Center – when you need a high quality CNC lathe that has BOTH – a high quality toolpost and tailstock.Built atop the uniquely designed solid cast base and lathe bed found in the larger FTH lathe models.

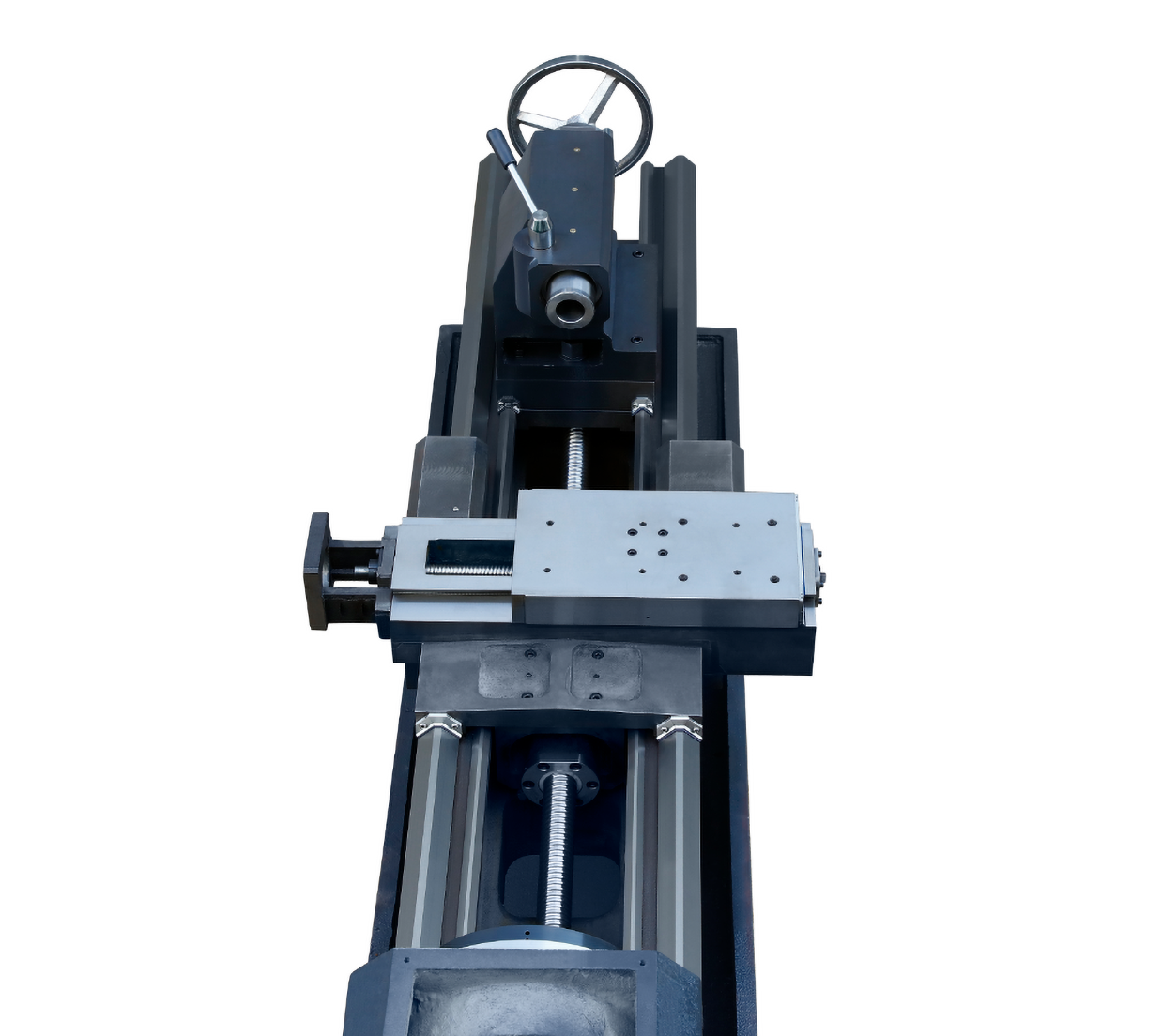

- The tailstock is set on its own guide way, parallel to the main bed ways. This structure is highly rigid and accurate

- Center mounted ball screws eliminate torque–providing better dynamic properties and greater stability over the life of the machine

- Servo drives on X/Z axes. Spindle can be driven by VFD or Servo

- Various control systems, chucks and tool mounting systems are available

SPECIFICATIONS

Capacity

- Chuck Size: 6″

- Max.Swing Dia. Over Bed: Ø300mm

- Max. Workpiece Length(center to center): 300mm

- Max. Swing Dia. Over Slide: Ø150mm

Spindle

- Spindle Bore: Ø48mm

- Max. Bar Capacity: Ø40mm

- Spindle Nose: A2-5

- Max. Spindle speed: 3000rpm, *4500rpm

- Spindle Power: 3.7kW, *5.5kW

Axis

- X Axis Travel: 280mm

- Z axis travel: 400mm

- X/Z axis rapid traverse: 9/12m/min

Tools

- 4-Station Toolpost, *8-Station Turret

- No. of tool stations: 4+2, *8

Tailstock

Tailstock Type: Manual, *Hydraulic

Quill Taper: MT3

Tailstock Quill Travel: 100mm

Tailstock Travel: 350mm

Others

- Bed Type/guideway: Flat/LM

- Power Capacity: 9KVA

- Overall Dimension(L×W×H): 1540x1010x1570mm

- Weight(about): 1500Kgs

Note: “*”means optional, “N/A”means not available.

Get Quotation Download Catalog