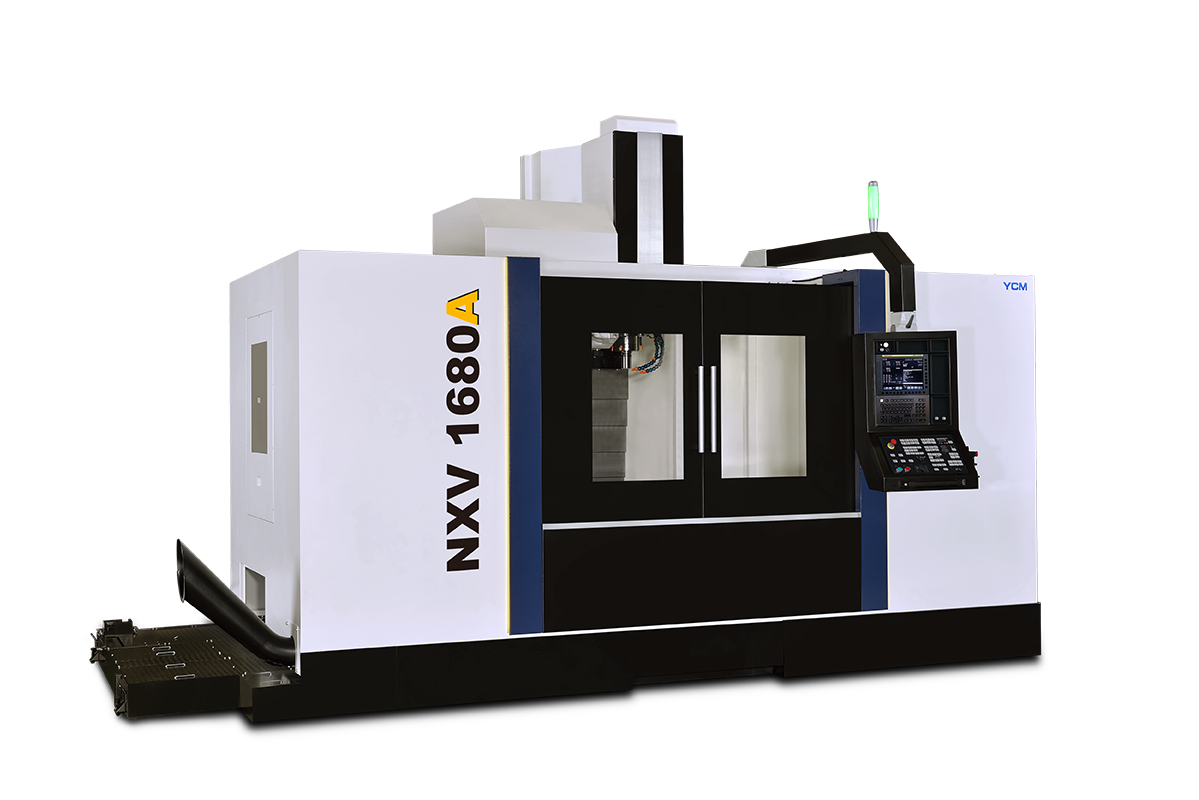

NXV1680A

Features

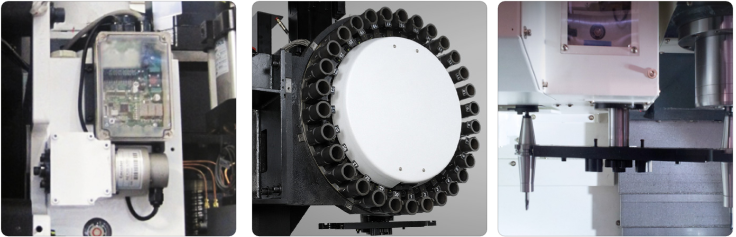

YCM In-house IDD Spindle

Tool unclamping cushion extends spindle bearing life by protecting spindle bearing from tool unclamping force.

Spindle cooling system (opt.) removes heat efficiently and minimizes thermal deformation.

Ceramic bearings features low inertia mass, low centrifugal force, high rigidity and low coefficient of thermal deformation.

High precision helical springs features high dynamic balance and low vibration.

Grease lubrication for 12,000 rpm spindle as a standard.

Oil-air lubrication for 12,000 / 15,000 rpm spindle (opt.)

High Rigidity Design

- FEM analysis is adopted to ensure the best mass arrangement and rib construction of the machine for constant stability under the intensive load of heavy-duty cutting.

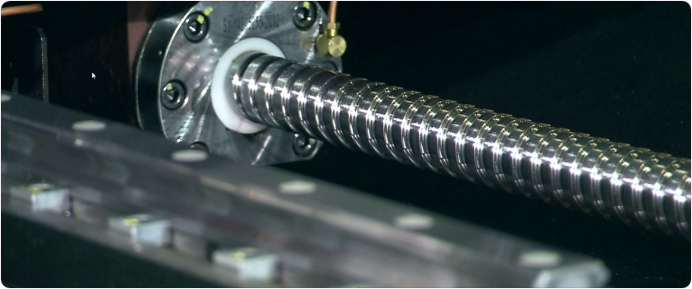

All axial AC servo motors equipped with Absolute Positioning Encoders, no zero return needed. - Direct drive provides backlash free, best accuracy, reliability and stability.

- High rigidity and high loading linear guideways applied on the three axes.

- 6 slide blocks on X-axis and 4 linear guideways on Y-axis

- No counter weight on Z-axis

- The rigid body construction makes for uncompromising precision and rigidity.

High Stability Tool Magazine

- Absolute encoder ATC system provides high stability and speed.

Inverter controlled, prevents tool change speed from changing under different power supply frequency. - Tool change speed can be adjustable for heavy tools.

- Auto Tool Change (T-T) 1.8 sec.

- Tool Magazine Capacity: 24T (30T/48T/60T opt.)

Automatic Tool Magazine Door Design

- Driven by pneumatic cylinder.

- Prevent coolant and chips from entering tool magazine.

Brand New Exterior Design

- Full enclosure exterior (including top cover).

- Convertible side window for convenient chip removal.

- Aesthetic rear cover design.

- Coolant shower for efficient chip removal

- Penta chip augers (4 Y-axial 1 X-axial) ensure fluent chip removal prevent chips from piling up. [Quad chip augers (4 Y-axial Chip Conveyor) opt.]

Specification Unit: Metric

| Product Name | unit | NXV1020A |

| Spindle | ||

| Spindle Speed (Opt.) | rpm | 12,000(15,000) |

| Spindle Power (Opt.) | kW | 18.5(18.5) |

| Spindle Taper (Opt.) | BBT40 | |

| Travel | ||

| X-axis Travel | mm | 1,630 |

| Y-axis Travel | mm | 762 |

| Z-axis Travel | mm | 700 |

| Distance Between Spindle Nose & Table Top | mm | 100~800

|

| Table | ||

| Table Size | mm | 1,730×760 |

| No. T-slot x Size x Pitch | mm | 7x18x100 |

| Max. Load on Table | kg | 1,500 |

| Feedrate | ||

| X/Y/Z Rapid Feedrate | m/min. | 30/30/24 |

| Cutting Feedrate | mm/min. | 1~20,000 |

| ATC | ||

| Tool Magazine Capacity (Opt.) | T | 24(30/48/60) |

| Tool Weight | kg/pc | 6 |

| Max. Tool Dimension (W/O Adjacent Tools) | mm | 24T : ø90 x 300 (ø140 x 300) 30T/40T/60T : ø76 x 300 (ø125 x 300) |

| General | ||

| Machine Weight | kg | 11,000 |

The manufacturer reserves the right to modify the design, specifications, mechanisms, etc. to improve the performance of the machine without notice. All the specifications shown above are just for reference.

Get Quotation

/home/alexpower/public_html/wp-content/themes/AlexPower/single-machines.php on line 11

/home/alexpower/public_html/wp-content/themes/AlexPower/single-machines.php on line 11