i-42 Robo

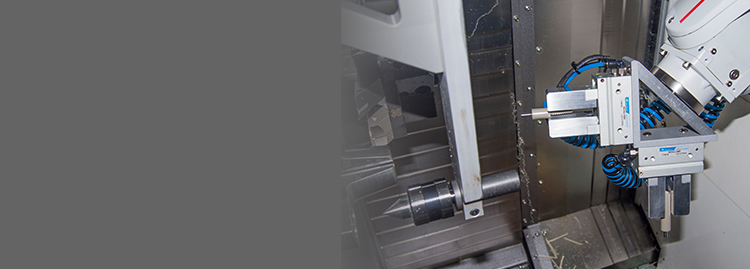

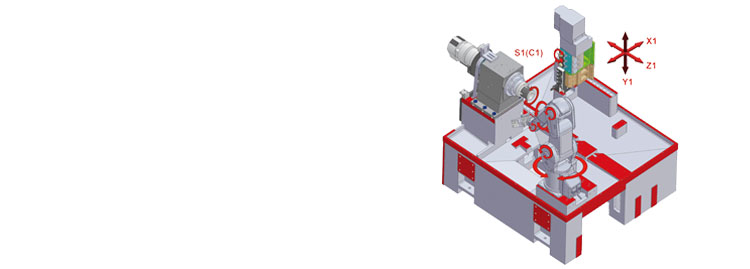

This 4 axis lathe with C-axis and live tooling provides the added advantage of robotic loading for unmanned chucking operations

This machine is a modified version of the IT-42 with internal integration of a Mitsubishi 6 axis articulated robot. This requires no additional floor space, and is positioned so it will not hinder the machine operator while setting the machine, or operating the Mitsubishi M70 control system.

INTELLIGENT ROBOT

Complimenting the standard IT-42 lathe, is a fully integrated high speed, high precision 6 axis robot.

This intelligent robot has a total of 88 programs, and can easily maneuver around tooling and other obstacles within the work area.

It can handle work pieces of up to 6kg, and is ideal for billets, castings and forgings.

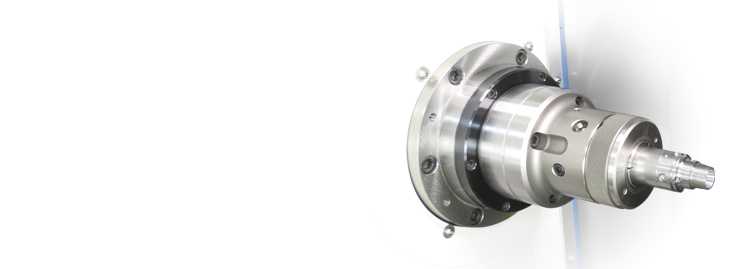

SPINDLE

The cartridge type spindle runs on P4 high precision bearings giving high radial and axial stability, allowing for heavy duty cutting.

The spindle is assembled and tested in a temperature controlled clean room, sealed, and requires no maintenance. The spindle housing is large, and symmetrically ribbed to allow heat dissipation and thermal stability.

LINEAR GUIDEWAYS

The machine is equipped with high precision, HIWIN linear guideways. The use of 35mm rails throughout the machine increases stability and accuracy, and allows heavier cuts to be achieved.

Specification

| Machine Type | I-42ROBO | |

| Mitsubishi Controller | M80 | |

|

Spindle

Capacity

|

Max. Turning Dia. | 100mm |

| Max. Bar Working Dia. | 42mm (65mm) | |

| Max. Turning Length | 230mm | |

| Collet Chuck Type | KK5-173E42B (KK6-185E60B) | |

| Spindle Nose | A2-5 (A2-6) | |

| Spindle Bore | 43mm (66mm) | |

| Max. RPM. | 4000rpm (6000rpm) | |

|

Sub-spindle

Capacity

|

Max. Turning Dia. | —- |

| Max. Bar Working Dia. | —- | |

| Max. Turning Length | —- | |

| Collet Chuck Type | —- | |

| Spindle Nose | —- | |

| Spindle Bore | —- | |

| Max. RPM. | —- | |

| Travel&Feed | X1/Y1/Z1 axis | 150 / 410 / 250mm |

| X2/Y2/Z2 axis | —- | |

| Rapid Feed | —- | |

|

Motor

|

Main-Spindle | Servo Spindle 7.5kw (11.0kw) |

| Sub-Spindle | —- | |

| X1/Y1/Z1 axis | AC Servo 1.0 / 1.5 / 1.5kw | |

|

X2/Y2/Z2 axis

|

—- | |

|

Motorized Tool

|

AC Servo 1.5k | |

|

A.T.C System

|

OD/ID Tools Main Spindle | 6 / 5 |

| OD/ID Tools Main Spindle | —- | |

| Tool Shank Size | □ 20mm | |

| Drill Holder Size (Main) | ER-20 / Ø20mm | |

| Drill Holder Size (Sub) | —- | |

| Motorized Tool | Number of Motorized Tools | 6 (12 with B-axis) |

| Max. RPM. | 4000rpm | |

| Collet Specification | ER-20 | |

| Max. Drilling Dia. | 12.0mm | |

| Max. Tapping Capacity | M10xP1.5 | |

|

Hydraulic

System

|

Hydraulic Pump / Tank Capacity | 1HP / 40L |

|

Max. Pressure / Flow

|

30 kg/cm² / 12L/min | |

| Lubrication | Lubricant Pump / Tank Capacity | 25W / 2L |

| Max. Pressure |

15 kg/cm²

|

|

|

Coolant

System

|

Coolant Pump | TPH4T5K, 5Bar, 75 L/min |

| Hydraulic Pump | ——- | |

|

Coolant Tank Capacity

|

125L | |

|

Machine

Size

|

Length/ Width/ Height | 3200 (2500) / 1750 / 1950mm |

| Weight |

4300kg

|

|

Get Quotation Download Catalog

/home/alexpower/public_html/wp-content/themes/AlexPower/single-machines.php on line 11

/home/alexpower/public_html/wp-content/themes/AlexPower/single-machines.php on line 11