PRECISION INTERNAL GRINDING MACHINE (8″3JAW)

MODEL

JAG-3JAW-AAL1 | JAG-3JAW-AL1

FEATURE

It is easy to operate and equip a special mechanism for step inner hole grinding (blind hole), such as screw mold.

STANDARD ACCESSORIES

- Ø3mm Collet x 1pc

- Ø6mm Collet x 1pc

- Nut(M14xP0.75) x1pc

- Tool Box and Accessories x 1set

APPLICATIONS

- Screw Mold Inner Hole

- Nut Mold Inner Hole

- Cold Or Hot Forge Big Tooling Inner Hole

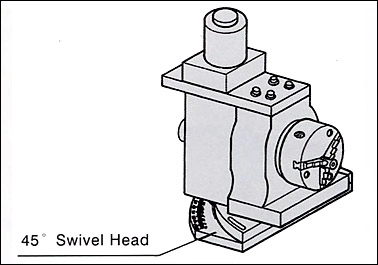

OPTIONAL ATTACHMENTS:

- ±45° Swivel Head

- Coolant System

- Vacuum Dust Collector

- Optical Meter

- Enlarge-Type internal Grinding Spindle (12000rpm~18000rpm)

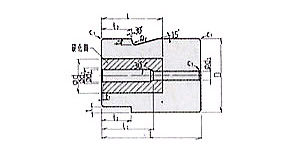

| Model | JAG-3JAW-AAL1 | JAG-3JAW-AL1 | |

|---|---|---|---|

| Clamping diameters | Ø2.5- Ø200mm | Ø2.5- Ø200mm | |

| Max. clamped unit length | 240mm | 240mm | |

| max. travel | front to back | 200mm | 200mm |

| left to right | 520mm | 520mm | |

| Cross feeding graduation | 0.0025mm | 0.0025mm | |

| Table speed | 0-4m/min | 0-4m/min | |

| Roller speed | 0-550 rpm | 0-550 rpm | |

| Swivel angle | ±5° | ±5° | |

| Feeding method | front to back | automatic | manual |

| left to right | automatic | automatic | |

| Spindle speed | 0-55000 rpm | 0-55000 rpm | |

| Main Motor | Roller | 1/2HP | 1/2HP |

| Spindle | 1HP | 1HP | |

| front to back | 5PHx1.4A | —- | |

| left to right | 2PHx2A | 2PHx2A | |

| Dimensions (LXWXH) |

1700×1100 | 1700×1100 | |

| x1700mm | x1700mm | ||

| Weight | 1400 Kgs | 1400 Kgs | |

| Working range (inner hole) | Ø1.5 – Ø80mm | Ø1.5 – Ø80mm | |

Get Quotation

/home/alexpower/public_html/wp-content/themes/AlexPower/single-machines.php on line 11

/home/alexpower/public_html/wp-content/themes/AlexPower/single-machines.php on line 11