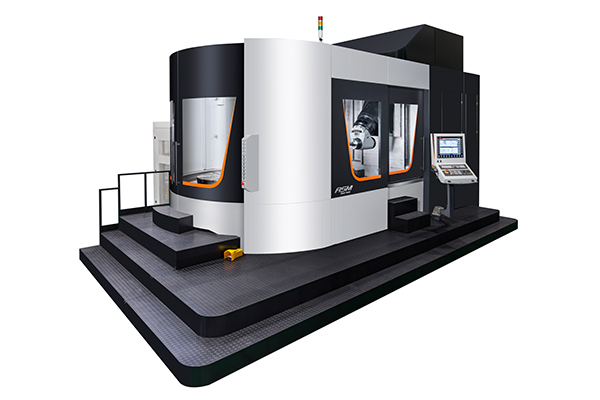

ASM/ASM-FD Series

Features

ASM is the first 5-axis CNC turning and milling machining center of Vision Wide, and it is particularly designed for delicate cylindrical components machining featuring high acceleration, rapid feed-rate, and synchronized axes machining, especially for aerospace components, tire molds, turbine blades, and aluminum parts.

ASM accessorizes with 5-axis universal head and rotary shafts built-in D.D motor. Through topology analysis, ASM realizes the best distance between the tool center point and B-axis transmission.

- Positioning P0.006mm

- Repeatability Ps0.0055mm

- Spindle thermal compensation 0.02 mm

- Rapid Traverse 40m/min

- Acceleration 0.3G

- Cutting Feed rate 24 m/min

specifications

| Model | Unit | ASM-1012 | ASM-1212 | ASM-1612 | ASM-1612G | ASM-1012 FD | ASM-1212 FD | ASM-1612 FD | ASM-1612G FD |

| X axis travel | mm | 1,000 | 1,250 | 1,620 | 1,620 | 1,000 | 1,250 | 1,620 | 1,620 |

| Y axis travel | mm | 1,260 | 1,260 | ||||||

| Z axis travel | mm | 1,050 | 1,050 | ||||||

| Table dimension | mm | Ø1,000 | Ø1,200 | Ø1,500 | Ø1,500 | Ø1,000 | Ø1,200 | Ø1,500 | Ø1,500 |

| Table load(central region) | kg | 2,000 | 2,000 | 3,000 | 3,000 | 2,000 | 2,000 | 3,000 | 3,000 |

| Spindle speed | rpm | 10,000 | 7,000 | 10,000 | 7,000 | ||||

| Cutting federate | mm/min | 1~24,000 | 1~24,000 | ||||||

| Rapid traverse(X/Y/Z) | m/min | 40 / 40 / 40 | 40 / 40 / 40 | 40 / 40 / 24 | |||||

※Please contact sales for more details.

Accessories

Standard Accessory & Function

- HEIDENHANIN TNC640 Controller

- 10,000 rpm/HSK-A100 (milling)

- HIEDENHAIN DCM (Dynamic Collision Monitoring)

- 45°universal head self-monitoring protection system:

- 4-1. B/C rotating motor overloading protection

- 4-2. Spindle and motor overloading protection

- 4-3. Spindle cutting vibration protection

- 4-4. Spindle overloading protected by software

- 45° universal head rotation error mechanism chain correction

- Spindle and structure thermal compensation system

- Spindle cooling system

- Spindle nose ring and side cutting coolant device

- Air blast through spindle

- Cutting fluid cooling system

- XYZ axis linear scale feedback

- XYZ-axis travel hard limits protection

- Centralized auto lubrication system

- Independent lubrication oil collector

- Wash gun and pneumatic interface

- Enclosed sheet metal guard with roof

- 40 tools magazine with vertical ATC

- Screw type chip conveyor on table sides

- Caterpillar type chip conveyor / Water tank

- Swiveling arm type operation panel

- Air conditioning for electrical cabinet

- Working lamp

- Operation cycle finish and alarm light

- Working lamp

- RJ45 interface

- Switch for tool clamping

- Remote monitoring software-standard

- Auto power off function

- Z axis retract function at power failure

- Foundation pads and bolts kits

- Adjustment tool and tool kits

- Technical manuals (operation, maintenance manual and circuit diagram)

Optional Accessory & Function

- SIEMENS 840D SL Controller

- 24,000 rpm/HSK-A63 (Milling)

- 10,000 rpm/HSK-T100 (Milling and Turning)

- 7,000 rpm/HSK-A100 (Milling, ASM-1612G only)

- 7,000 rpm/HSK-T100 (Milling and Turning, ASM-1612GFD only)

- Coolant through spindle system 20 / 60 bar

- The interface of coolant through spindle

- Coolant through spindle system and air through spindle

- Air through spindle ring

- Oil skimmer

- Oil mist cooling device

- Oil mist recycle device

- Spin window

- Helical bladed screw conveyor on table sides

- Chip clean flushing device on table side grooves

- Chip clean flushing device at roof

- Dual belt type chip conveyor

- Chip cart

- 60/119T tools magazine with vertical ATC

- Auto tool length measurement

- Auto workpiece coordinate measurement

- XYZ axis absolute pulse coder feedback

- XYZ axis independent manual pulse generator

- Remote monitoring software-professional

- Smart federate machining function

- Transformer

- Transformer and voltage stabilizer

- Auto warm up

- APC (Auto Pallet Change Device) to exchange table

- Wraparound monolithic stairs (limited to APC for ASM-1012/1212 )

Get Quotation