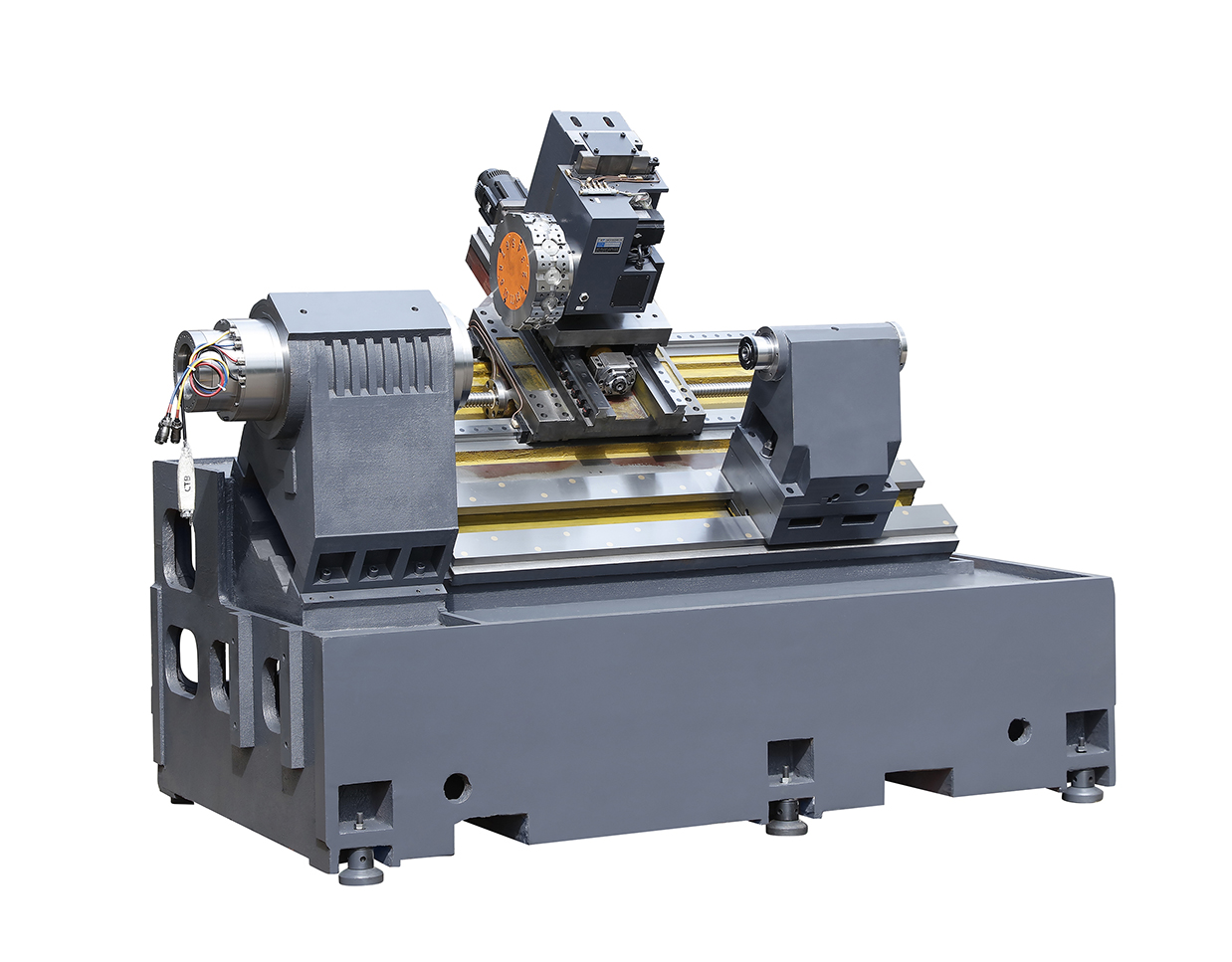

DT500E-S

The models can satisfy a wide range of users from beginners of shop production to group corporation with experienced technicians.

- Meehanite advanced casting on main machine body adoption with reasonable design and optimized layout assures machine accuracy and reliability in long life service.

- X, Z and E Axes adopt precision linear guideway with big span layout, solid structure and rigidity machine bed for good accuracy in long term.

- High speed rigidity spindle plus built-in electrical sub spindle realizes high precision,high load and high speed during machining.

- 12-station double-position turret with bi-directional positioning for fast tool change and accuracy positioning.

- Precision ballscrews with preload technology on both axes minimizes thermal deformation, maximize transmission accuracy.

- Applied in automatic production of autoparts, devices, electrical products, mechancial products etc.

SPECIFICATIONS

Capacity

- Swing Over Bed Diameter: Ø650mm

- Max. Workpiece Swing Diameter: Ø430mm

- Max. Turning Diameter: Ø320mm

- Max. Turning Legngth: 650mm

Spindle

- Main Spindle Speed: 4000mm

- Main main motor: 22.0/30.0kW

- Main Spindle nose: A2-6

- Main Spindle Chuck size: 8″

- Main Spindle Bore: Ø62mm

- Main Spindle Drawbar Capacity: Ø51mm

- Sub Spindle Speed: 5000mm

- Sub main motor: 11.0/ 15.0kW

- Sub Spindle nose: A2-5

- Sub Spindle Chuck size: 6″

- Sub Spindle Bore: Ø55mm

- Sub Spindle Drawbar Capacity: Ø45mm

Axis

- X/ Y/ Z Axis Travel: 250mm/ 100mm/ 650mm

- X/ Y/ ZAxis Rapid feed traverse: 20/ 12/ 20m/min

Tools

- Type: BMT45

- Number of Tool Stations: 12

- Tool size: 20×20mm/ ∅32mm

Tailstock

- N/ A

Others

- Overall Dimension(L×W×H): 3000×1780×2050mm

- Machine Weight: 5300Kgs

Note: “*”means optional, “N/A”means not available.

Get Quotation Download Catalog

/home/alexpower/public_html/wp-content/themes/AlexPower/single-machines.php on line 11

/home/alexpower/public_html/wp-content/themes/AlexPower/single-machines.php on line 11