NT-2500SY

features

IDEAL STRUCTURAL RIGIDITY AND DESIGN

30° One-piece Slanted Bed Design: Extends the space for chips removal.

Highly Rigid Bridge Type Base:Effectively absorbs vibration and reduces structural deformation.

Enlarged Box Guideway Width:The oversized guideways are treated through induction hardening process and precision ground to achieve optimal rigidity, accuracy, and longevity.

Fast & Reliable Motorized Turret:Servo-driven design achieves fast tool changing time and reliable indexing.

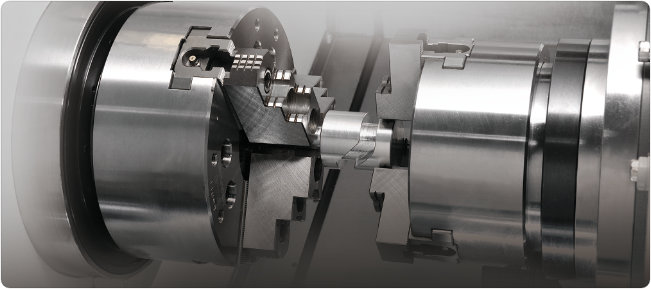

YCM IN-HOUSE BUILT-IN MOTORIZED MAIN AND SUB SPINDLE

- The built-in spindle design alleviates tension, slip and vibration generated by traditional belt-driven spindle design. With large diameter bearing, it greatly improves rigidity.

- The built-in spindle is circulated cooled and controls temperature growth with oil cooling system, so as to reduce thermal deformation and improve spindle speed.

- The spindle utilizes large diameter bearing that improves rigidity. Combining bearing characteristics and radial, axial and synthetic loads that ensures the spindle perform high precision turning and heavy duty cutting at low speed.

- C-axis index: 0.001°.

Flexible Y-axis Capability

- Y plus C-axis integrates mill/turn process and fulfills numerous complex requirements which can do more than general lathes.

- Direct drive motors on X/Y/Z/B-axis reduce backlash and vibration problems and achieve accurate positioning.

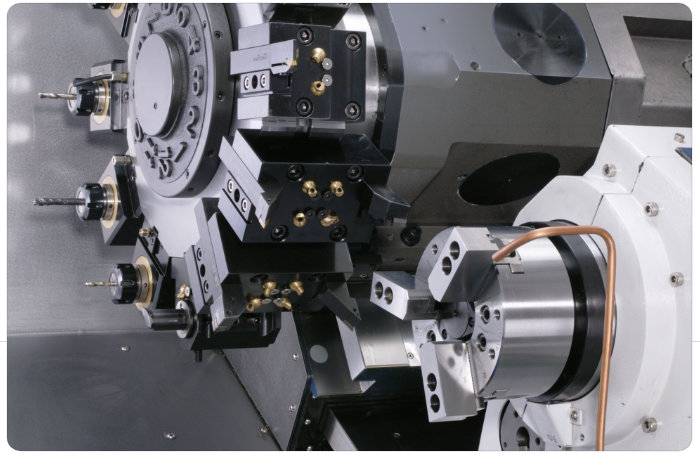

FAST & RELIABLE MOTORIZED TURRET

- 12 tools capacity. All stations are available for live tools.

- The radial power turret combines turning and milling capacities that reduces turret interference.

- The turrets are servo motor driven with hydraulic clamping design for saving tool change time.

- With highly accurate big diameter coupling, the higher positioning accuracy and repeatability accuracy they will be.

Specifications Unit : Metric

| Product Name | unit | NT-2500SY |

| Machining Capacity | ||

| Max. Turning Diameter | mm | ø350 |

| Max. Turning Length | mm | 686 |

| Main Spindle | ||

| Chuck Size | 10 | |

| Spindle Nose | A2-8 | |

| Hole Through Spindle | mm | ø91 |

| Hole Through Draw Bar | mm | ø75 (ø80) |

| Spindle Speed | rpm | 3,500 |

| C-axis Speed | rpm | 50 |

| Sub Spindle | ||

| Chuck Size | 6 | |

| Spindle Nose | A2-5 | |

| Hole Through Spindle | mm | ø43 |

| Hole Through Draw Bar | mm | ø33 |

| Spindle Speed | rpm | 6,000 |

| C-axis Speed | rpm | 50 |

| Travel | ||

| X-axis Travel | mm | 260(175+85) |

| Z-axis Travel | mm | 780 |

| Y-axis Travel | mm | 100 (±50) |

| B-axis Travel | mm | 770 |

| Feedrate | ||

| “X – axis Rapid Feedrate / Cutting Feedrate” | m/min / mm/min | 20 / 1~10,000 |

| “Z – axis Rapid Feedrate / Cutting Feedrate” | m/min / mm/min | 24 / 1~10,000 |

| “Y -axis Rapid Feedrate / Cutting Feedrate” | m/min / mm/min | 10 / 1~10,000 |

| “B -axis Rapid Feedrate / Cutting Feedrate” | m/min / mm/min | 20 / 1~10,000 |

| ATC | ||

| Motor | ||

| Main Spindle Motor | kW | 15/22 |

| Sub Spindle Motor | kW | 5.5/7.5 |

| Turret | ||

| Turret Type | Radial Power Turret | |

| Turret Capacity (opt.) | 12T(16T) | |

| Live Tool Motor Speed | rpm | 4,500 |

| Live Tool Motor Torque | kgf-m | 3.6 |

| Swing Over Turret | mm | ø720 |

| Tailstock |

| General | ||

| Machine Weight | kg | 7,450 |

The manufacturer reserves the right to modify the design, specifications, mechanisms, etc. to improve the performance of the machine without notice. All the specifications shown above are just for reference.

Get Quotation