RSB-32/38(Y)

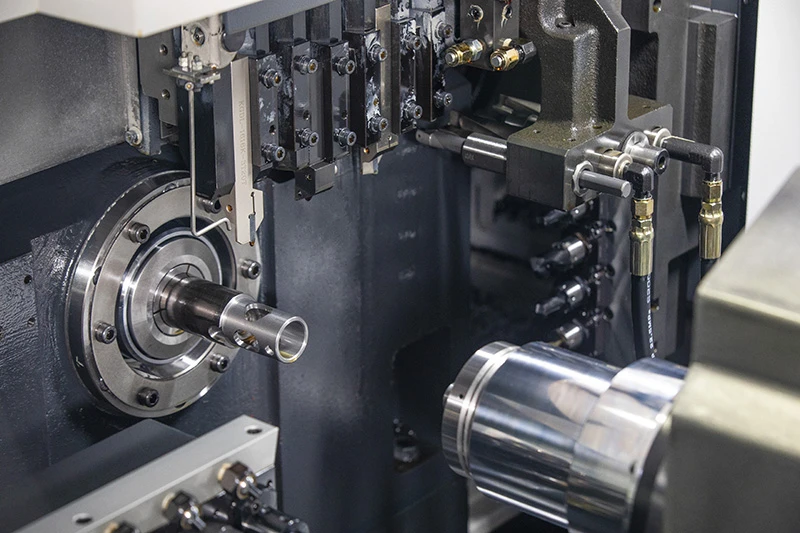

Flexibly corresponds to various machining, from simple machining to complex machining. The G.B type can be used to regulate material deflection and achieve accurate machining. For short parts, the N.G.B type can be used to minimize the residual material length and reduce the material cost.

FEATURE

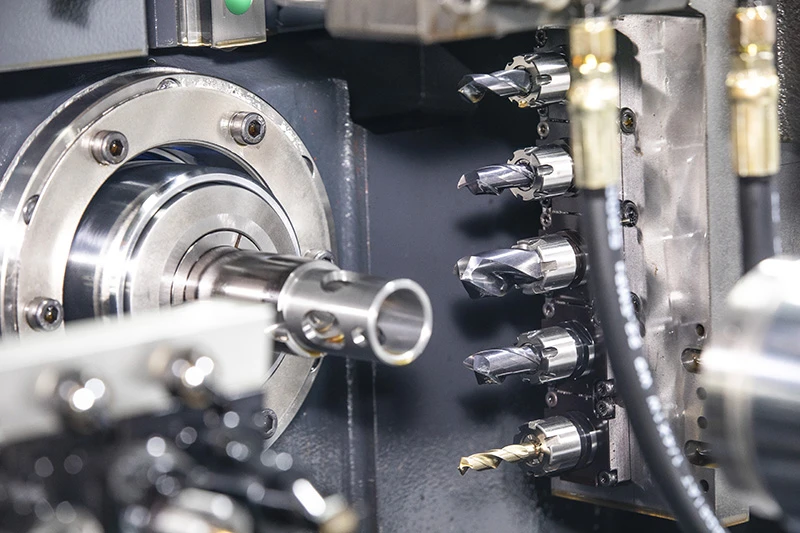

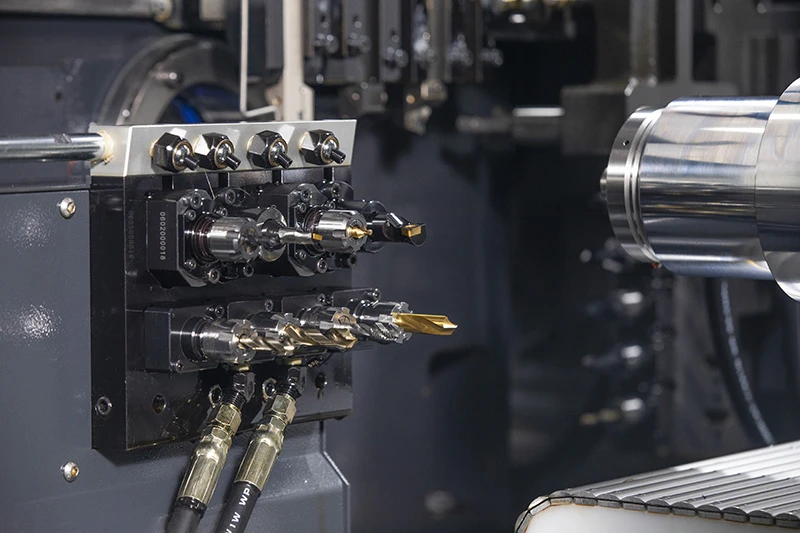

- Design to adopt various tooling options. You can choose optimal tooling to achieve level of productivity. For example thread whirling unit, polygon unit, Slotting unit, and etc….

- Powerful Back end Tool Station come with total 8 pcs of Live tools , Standard are 4 pcs and Fixed tool 4 pcs. (RSB-32Y/38Y Only)

SPECIFICATION

| Main Spindle | Model | RSB-32 | RSB-32Y | RSB-38 | RSB-38Y |

|---|---|---|---|---|---|

| Max. Machining Diameter (Revolving Guide Bush) | Ø 32 mm | Ø 38 mm (N.G.B Ø42 mm) |

|||

| Max. Turning Length (Revolving Guide Bush) | 200 mm | 200 mm | |||

| Max. Turning Length (Non Guide Bush) | Material Dia. x 2.5 (Max.50 mm) | Material Dia. x 2.5 (Max.50 mm) | |||

| Min. Input Unit | 0.001 mm | 0.001 mm | |||

| O. D. Tool | □16mm x 6 pcs | □16mm x 6 pcs | |||

| Sleeve Holder | C25-ER16 – 4 pcs | C25-ER16 – 4 pcs | |||

| Power Driven Tool | ER16 x 5 pcs | ER20 x 5 pcs | |||

| Power Driven Driver Motor | 1.5 kW | 2.2 kW | |||

| Power Driven Tool Max. Speed | 6,000 rpm | 6,000 rpm | |||

| Spindle Motor | 3.7 / 5.5 kW | 5.5 / 7.5 kW | |||

| Main Spindle Speed | 8,000 rpm | 6,000 rpm | |||

| Sub Spindle | Max. Machining Diameter | Ø 32 mm | Ø 38 mm | ||

| Max. Length for Front Ejection | 50 mm | 50 mm | |||

| Max. Parts Projection Length | 30 mm | 30 mm | |||

| Back 4 – Spindle Holder | ER16 x 4 pcs | ER16 x 8 pcs | ER16 x 4 pcs | ER16 x 8 pcs | |

| Max. Sub Spindle Speed | 6,000 rpm | 6,000 rpm | |||

| Sub Spindle Motor | 3.7/5.5 kW | 5.5/7.5 kW | |||

| Power Driven Driver Motor | 1.0 kW | 1.0 kW | |||

| Power Driven Tool Max. Speed | 6,000 rpm | 6,000 rpm | |||

| General | Axis Rapid Speed | 30 m/min | 30 m/min | ||

| Hydraulic Pump | 0.75 kW | 0.75 kW | |||

| Coolant Tank Capacity | 150 L | 150 L | |||

| Coolant Pump Motor | 960 W | 960 W | |||

| Machine Dimension | 2757 x 1456 x 1830 mm | 2757 x 1456 x 1830 mm | |||

| Machine Weight (N. W.) | 3800 kg | 3900 kg | |||

| Power Supply | AC/3PH/220V/20 kW | AC/3PH/220V/20 kW | |||

| CNC Controller | MITSUBISHI-M80 | MITSUBISHI-M80 | |||

Standard Accessories

- Operation Panel 10.4 inch Color LCD Display

- C-Axis Control (Main & Sub Spindle)

- O.D. Tool Holder

- 4 Tool Sleeve Holder

- Back Machining 8 Spindle Tool Unit (RSB-32Y/38Y)

- Coolant Flow Detector

- Air Cleaning for Revolving Guide Bush

- Parts Ejection Detector

- Pneumatic Unit

- Parts Conveyor

- Revolving Guide Bush

- C-Axis Control (Main & Sub Spindle)

- O.D. Tool Holder

- 4 Tool Sleeve Holder

- Back Machining 8 Spindle Tool Unit (RSB-32Y/38Y)

- Coolant Flow Detector

- Air Cleaning for Revolving Guide Bush

- Parts Ejection Detector

- Pneumatic Unit

Optional Accessories

- Non-Guide Bushing Holder

- Chip Conveyor with Cart

- High Pressure Coolant Device (30bar / 70bar)

- Auto Stabilizer

- 3-Spindle Front Power Driven Tool Unit

- Thread Whirling Unit

- Slotting Unit

- Non-Guide Bushing Holder Auto Bar Feeder Machine

- Chip Conveyor with Cart Long Part Ejector with Guide Tube

- High Pressure Coolant Device (30bar / 70bar) Oil Mist Collector

- Auto Stabilizer CE Marking Version

- 3-Spindle Front Power Driven Tool Unit 2-Spindle Front Power Driven Tool Unit

- Thread Whirling Unit Polygon Unit

- Slotting Unit Auto Stabilizer & Transformer

Design and specification are subject to change without prior notice.

The sound pressure level is 80 dB(A) at the position of one meter outside the machine