SA28-S

Meet the new low cost option for dual sindle machining. Advantages of dual spindle/ turret machining centers include: 1) One machine is cheaper than two 2) More accurate when a machine process is accomplished one a single machine rather than otherwise 3) lower labor cost due to reduced set-up requirements. In the past, the problem with dual spindle machines has been the price-too high to justify. Z-MaT has now introduced the SA28-S Dual Spindle Turning Center. This high quality machine has the capabilities of traditional dual spindle machines-at a much lower price tag. Finally, here is an automation option you can use-and price justify.

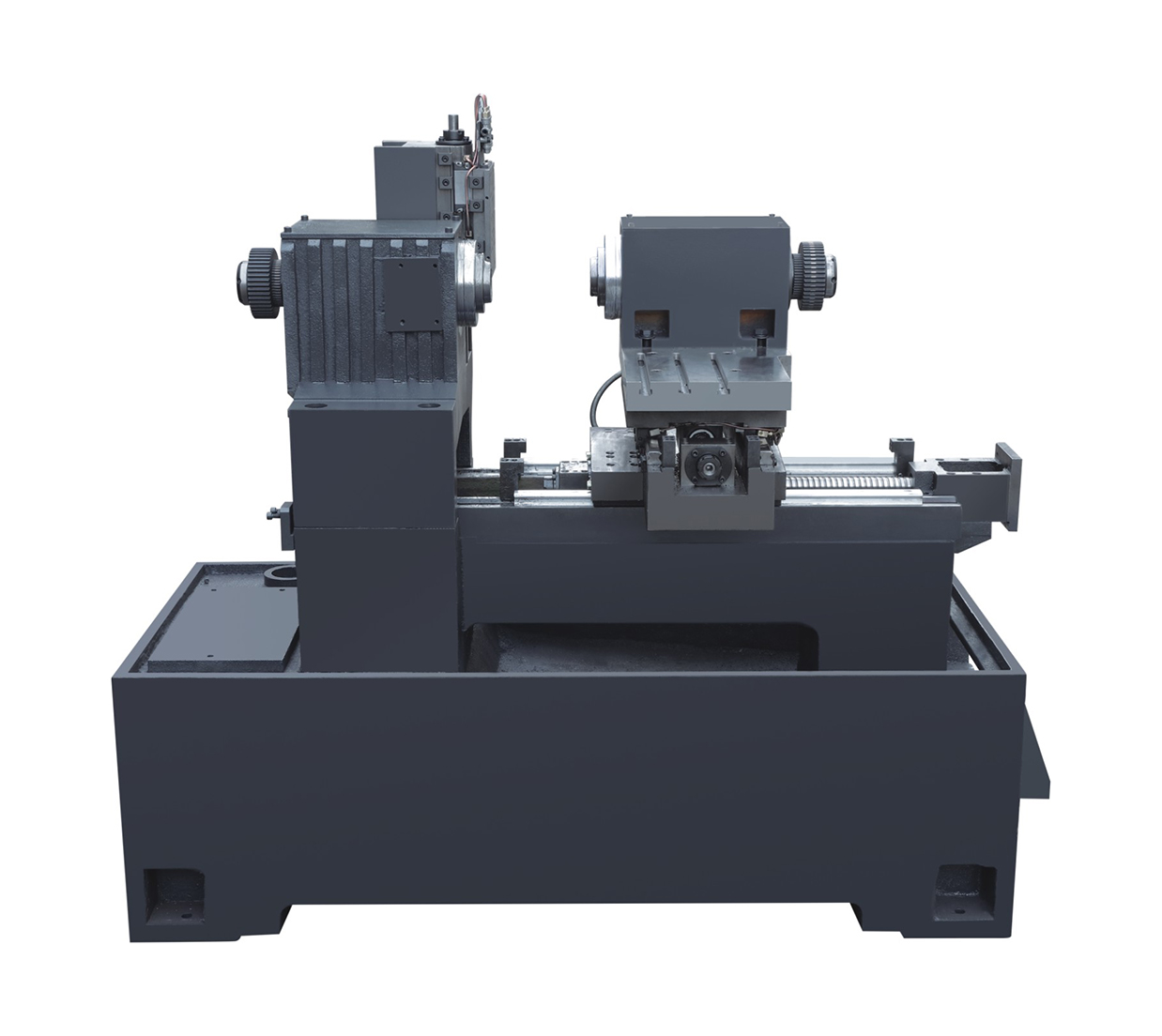

- Highly rigid frame structure with wide span provides high stability and heavy carrying capacity

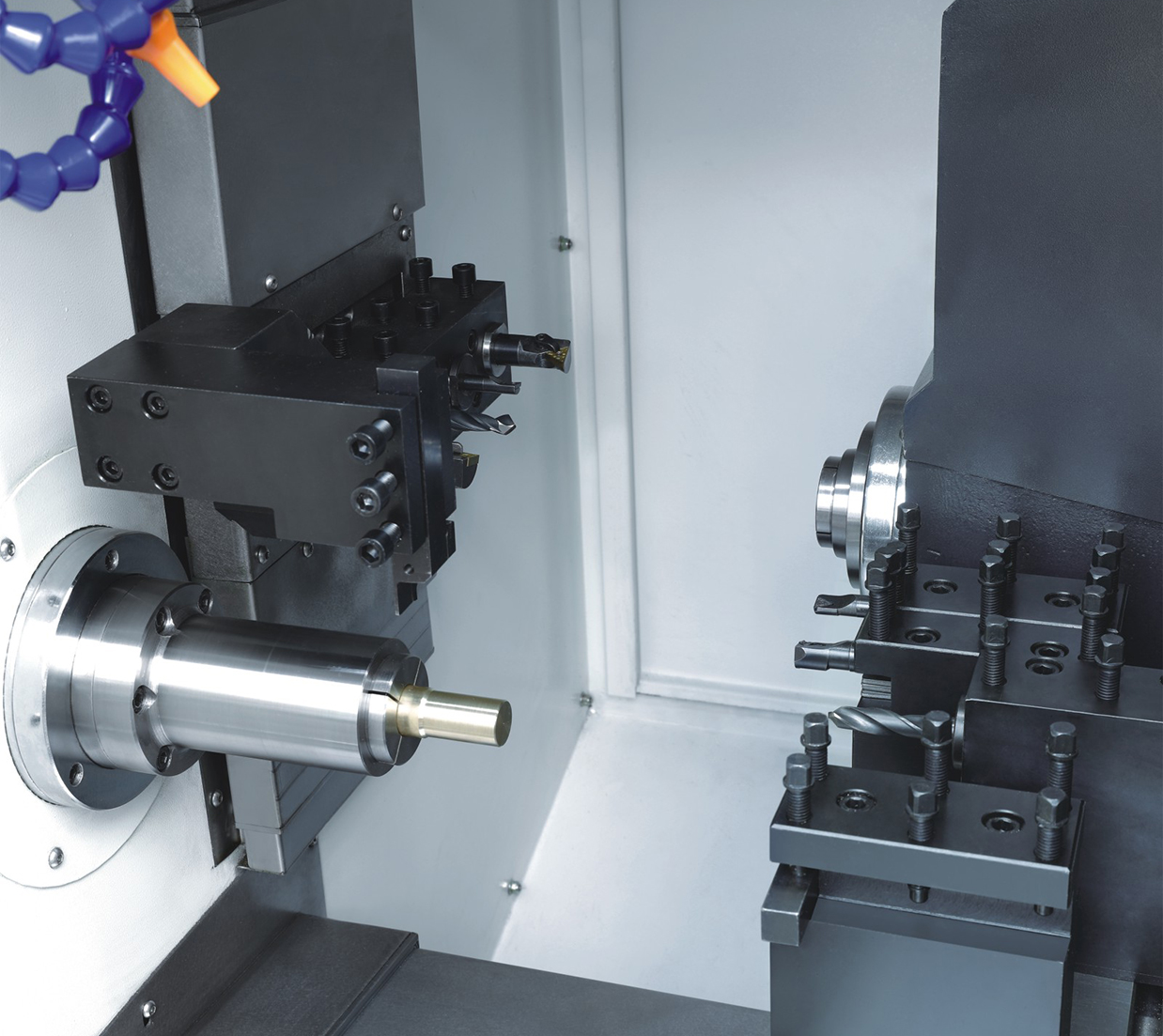

- X Axis secondary spindle is mounted on the machine carriage. Y axis spindle is mounted on the side of headstock

- Center mounted ball screw eliminates torque-increasing speed and efficiency. Dual, proload bearing structures support ball screws for optimal transmission accuracy

- Machine base and bed are one-piece casting, mono-block design. This provides optimal rigidity and accuracy.

SPECIFICATIONS

Capacity

- Standard Machining Diameter: ∅40mm

- Max. Bar Capacity: ∅28mm

Spindle

- Main Spindle Bore: ∅37mm * ∅48m

- Max. Bar Capacity on Main spindle: ∅28mm *40mm

- Max. Spindle speed: 3000rpm

- Spindle power: 3.7Kw

- Spindle Type: ∅68mm

- Spindle Taper: 39°,*42°Sub Spindle Bore: ∅37mm

- Max. Bar Capacity on Sub spindle: ∅28mm

- Max. Sub Spindle speed: 3000rpm

- Sub Spindle power: 2.2kW

Axis

- X Axis Travel: 350mm

- Z Axis Travel: 200mm

- Y Axis Travel: 80mm

- X/ Y/ Z Rapid Traverse: 15/15 m/min

Tools

- Gang type tools, *8-station turret(main tool carriage)

- TailstockN/ A

- Gantry Robot

Others

- Dimension(L×W×H): 1990×1480×1830mm

- Weight: 1900Kg

Note: “*”means optional, “N/A”means not available.