T8TY / T8MY

T8 Twin-Y / T8 Mill-Y

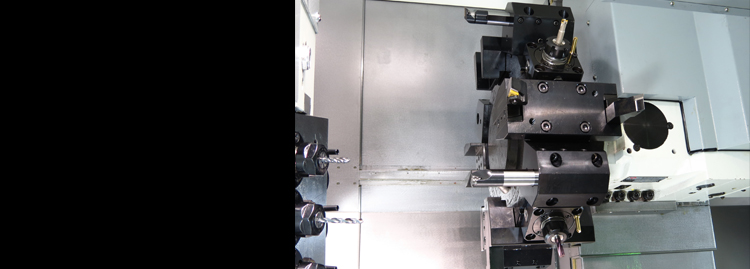

This new series offers the best conditions for challenging turning or milling operation and is designed primarily for heavy duty turning/milling operation with great mass production efficiency.

The T8 series offers three combinations for varieties of mass production given better access to the turret and 8” or 10 “ chuck and also efficient chip removal.

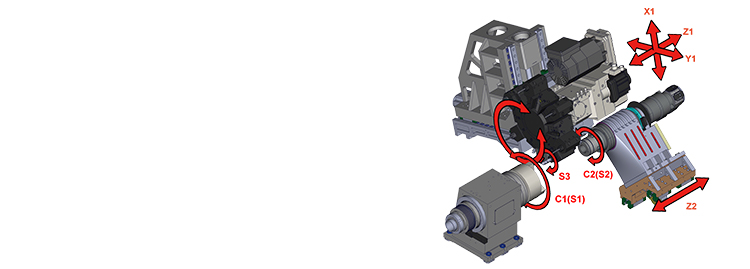

Twin spindle

This series packed with sub spindle and BMT turret with 12 stations which can be additionally equipped with driven tools on six stations. In connection with the driven tools, the main spindle is C-axis functional for accurate positioning.

T8_TWIN AXIS

The T8 series offers ditterent combinations for varieties of mass production given better access to the turret and 8” or 10 “ chuck and also efficient chip removal.

LINEAR GUIDEWAYS

The guide ways are rectangular box section to maintain rigidity in prolonged operation. This high rigidity structure ensures high machine dynamics and superior machining accuracy.

Furthermore, all the axes equipped with 32mm diameter C5 class high precision ball screw, mounted with double ballscrew support bearing ( P4 class), assures high positioning accuracy and backlash free transmission.

Specification

| Machine Type | T8 TWIN-Y | T8 Mill-Y | |

| Mitsubishi Controller | M80 | M80 | |

|

Main Spindle

Capacity

|

Swing over Bed | 500mm | 500mm |

| Swing over cross slide | 300mm | 300mm | |

| Max. Turning Dia. | 300mm | 300mm | |

| Max. Bar Working Dia. | 65mm | 65mm | |

| Max. Turning Length | 150mm | 150mm | |

| Chuck Size | KK6-185E60B | KK6-185E60B | |

| Main Spindle Nose | A2-6 | A2-6 | |

| Main Spindle Bore | 66mm | 66mm | |

| Max. RPM. | 3000rpm (4000rpm) | 3000rpm (4000rpm) | |

|

Sub- Spindle

Capacity

|

Max. Turning Dia. | 200mm | —– |

| Max. Bar Working Dia. | 42mm | —– | |

| Max. Turning Length | 150mm | —– | |

| Chuck Size | KK5-173E42B | —– | |

| Sub- Spindle Nose | A2-5 | —– | |

| Sub- Spindle Bore | 32mm | —– | |

|

Max. RPM.

|

4000rpm (6000rpm) | —– | |

| Tavel&Feed | Slant Bed Degree | 75° | 75° |

| X1/Z1 Axis Travel | 150mm / 380mm | 150mm / 380mm | |

| Y1 Axis Travel | 80mm = ±40mm | 80mm = ±40mm | |

|

X2/Y2/Z2 Axis Travel

|

— / — / 385mm |

470mm / 380mm / 280mm

|

|

| Axes | Ball screw | Ø32mm-P10 | Ø32 Î P10 |

| Linear Guide Way | 35mm | 35mm | |

| Y2 Axis Linear Guide Way | —– | —– | |

| Rapid Feed | 30m/min | 30m/min | |

|

ATC System

|

System 1 | BMT-55 Power Turret | BMT-55 Power Turret |

| No of Tools | 12 | 12 | |

| Tool Holder | □25mm / ○25mm / ○32mm | □25mm / ○ 25mm / ○ 32mm | |

| System 2 | —– | —– | |

| No of Tools | —- | —– | |

| B Axis (option accessory) | —- | —– | |

|

Tool Holder

|

—- | —– | |

| Motor | Main Spindle | Servo Spindle 11kw | Servo Spindle 11kw |

| Sub Spindle | Servo Spindle 3.7kw (5.5kw) | —– | |

| X1/Y1/Z1 Axis | AC Servo 2.2 / 1.5 / 1.5kw | AC Servo 2.2 / 1.5 / 1.5kw | |

| X2/Y2/Z2 Axis | AC Servo — / — / 1.5kw | —– | |

| Hydraulic System | Pump Spec/Capacity | 1HP / 40L | 1HP / 40L |

| Hydraulic Pressure/ Flow | 30 kg/cm² / 12L/min | 30 kg/cm² / 12L/min | |

| Lubrication | Pump Spce/Capacity | 25W / 2L | 25W / 2L |

| Max. Pressure |

15 kg/cm²

|

15 kg/cm² | |

| Coolant System | Pump Spec | TPH4T5K, 5Bar, 75 L/min | TPH4T5K, 5Bar, 75 L/min |

| High Pressure Pump Spec | SF-30C, 25Bar, 30L/min | SF-30C, 25Bar, 30L/min | |

| Coolant Tank Capacity | 240L | 240L | |

| Machine Size | Length without/with Chip Coveyor | 2450mm/3350mm | 2450mm/3350mm |

| Machine Width/Height | 1650mm/1750mm | 1650mm/1750mm | |

| Machine Weight | 5700 kg | 5500 kg | |

/home/alexpower/public_html/wp-content/themes/AlexPower/single-machines.php on line 11

/home/alexpower/public_html/wp-content/themes/AlexPower/single-machines.php on line 11