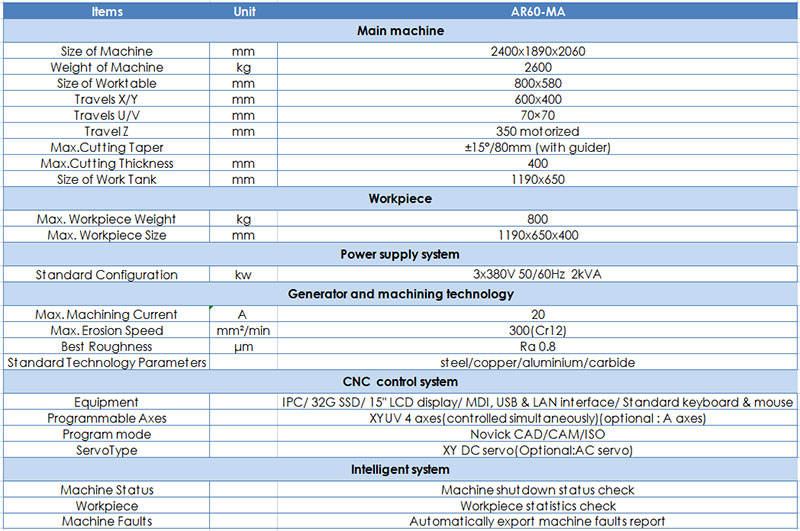

AR60-MA Precise CNC Reciprocal wire-cut EDM

R & D Software System of AR-MA Series Features

1. Include multi-time cut technics parameters data of steel, copper, aluminum ,carbide, titanium alloy and so on.

2. Deal with sharp angle especially

3. CNC of X/Y/U/V axes

4. 7 kind of languages: English/ Spanish/ Portuguese/ Russian/ Italian/ Polish/

5. Inch/metric transition

————————————————————————–

1. The auto-programming system can draw pictures, and create ISO code.

2. Support zoom machining and mirror machining

3. Mirror-image function and axes-exchange function

4. Auto-making multi-time cut machining program

————————————————————————–

1. Auto-diagnosis function

2. Real-timely multitasking control system

3. Files management

4. Track machining contrail

————————————————————————–

1. Display machining time

2. Setup offset

3. Modify technology parameters in real time

4. Memory the state of the power-off

5. Offset of pitch error for X/Y/U/V axes

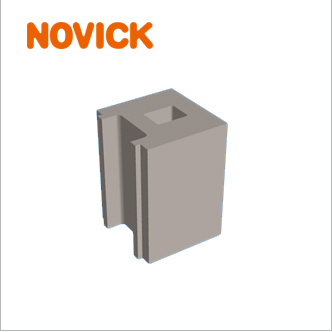

Cut Samples

| Workpiece material | Cr12 |

| Workpiece circumference | 907mm |

| Thickness | 30mm |

| Wire diameter | 0.18mm |

| Machining time | 165min |

| Cutting times | 1 cut+2 trim cuts |

| Machining accuracy | +/- 1.0μm |

| Roughness | Ra 1.0μm |

| Workpiece material | Cr12 |

| Workpiece circumference | 415mm |

| Thickness | 50mm |

| Wire diameter | 0.18mm |

| Machining time | 625min |

| Cutting times | 1 cut+3 trim cuts |

| Machining accuracy | +/- 1.0μm |

| Roughness | Ra .9μm |

| Workpiece material | Cr12 |

| Workpiece circumference | 132mm |

| Thickness | 30mm |

| Wire diameter | 0.18mm |

| Machining time | 125min |

| Cutting times | 1 cut+3 trim cuts |

| Machining accuracy | +/- 1.0μm |

| Roughness | Ra 1.0μm |

| Workpiece material | Cr12 |

| Workpiece circumference | 271mm |

| Thickness | 30mm |

| Wire diameter | 0.18mm |

| Machining time | 205min |

| Cutting times | 1 cut+2 trim cuts |

| Machining accuracy | +/- 1.0μm |

| Roughness | Ra 1.0μm |

/home/alexpower/public_html/wp-content/themes/AlexPower/single-machines.php on line 11

/home/alexpower/public_html/wp-content/themes/AlexPower/single-machines.php on line 11