HQ-650NCAD

Features

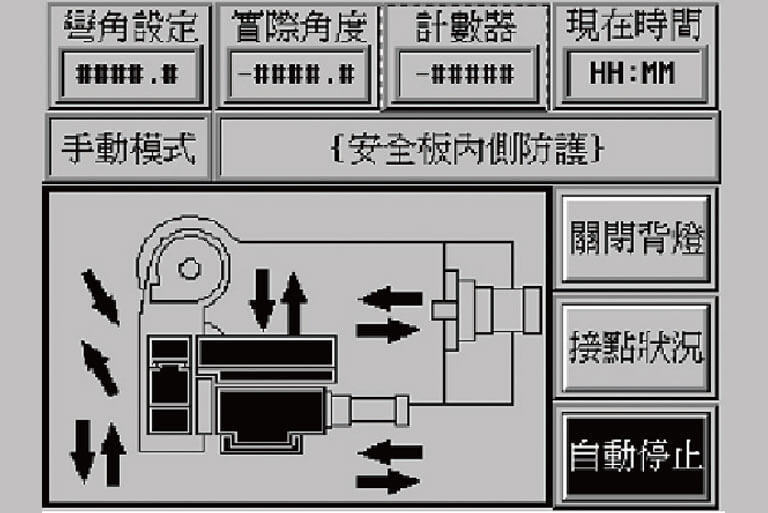

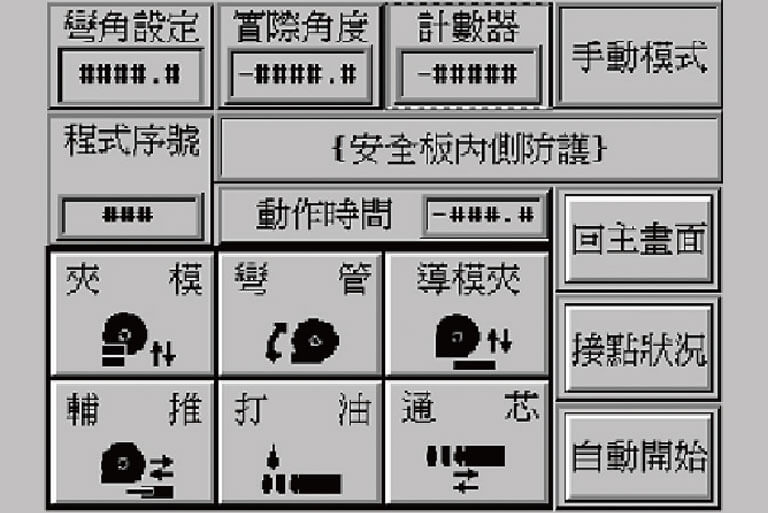

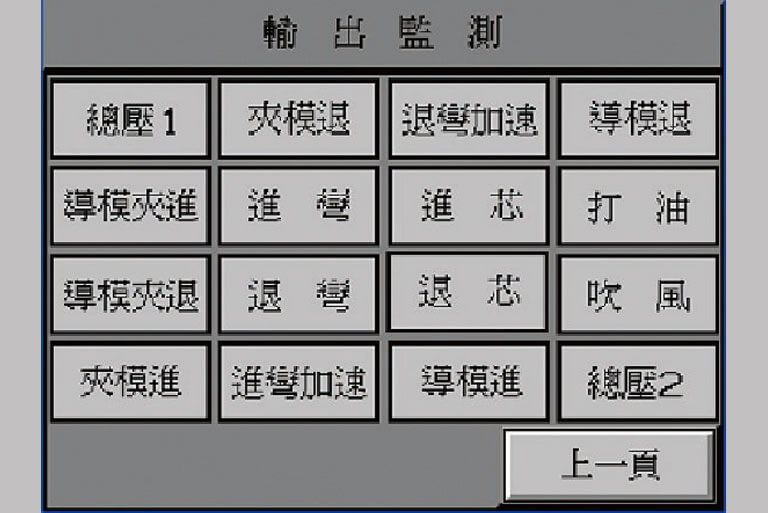

Figure-touched interface

- Figure-touched interface – simply touch the corresponding figures & words to proceed the operation.

- The panel displays the movement situation of the machine and bending angle.

The characters of Controller

- Operation Mode manual, semi-automatic, fully-automatic, program input and modification.

- Control-axis Bending axis C

- Max. Bends / per program : 16 Bends.

- Max. Memorized Programs : 200 sets.

- Action setting workload counter, mandrel on/ mandrel off option, Pressure die booster function, slow mandrel-backward function / special equipment.

Architecture

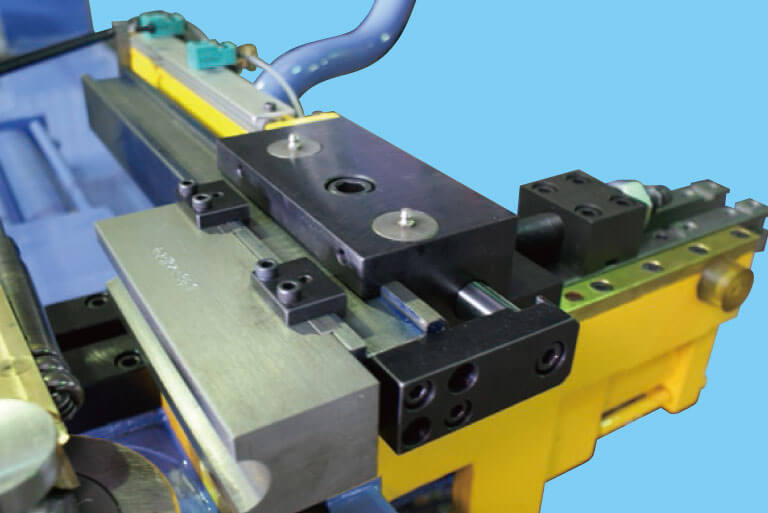

- Pressure die booster is controlled by individual hydraulic cylinder that enhances the processing stabilization.

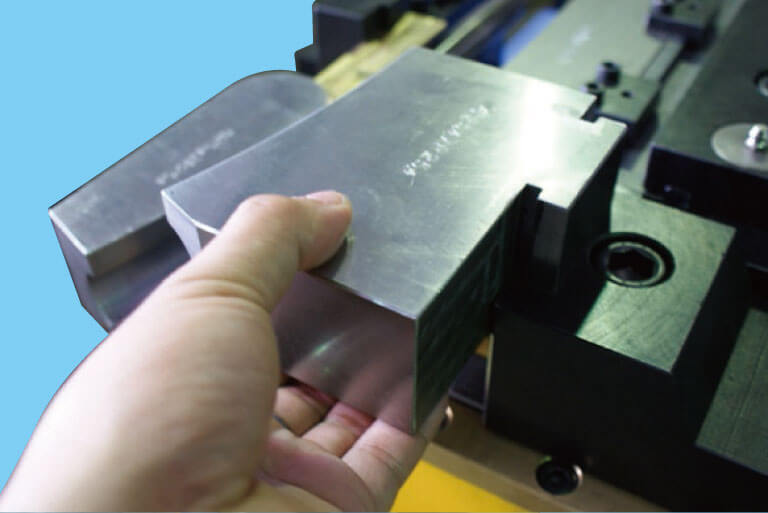

- The quick tooling change system is favor of production.

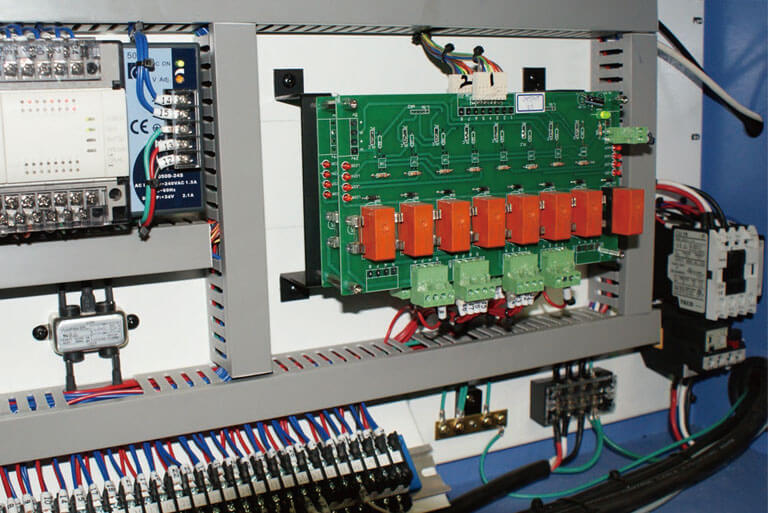

Modularized design

- Modularized design on circuit, easy maintenance and replacement.

- Auto detective and error movement indicating functions prevent machine from being damaged by wrong operation.

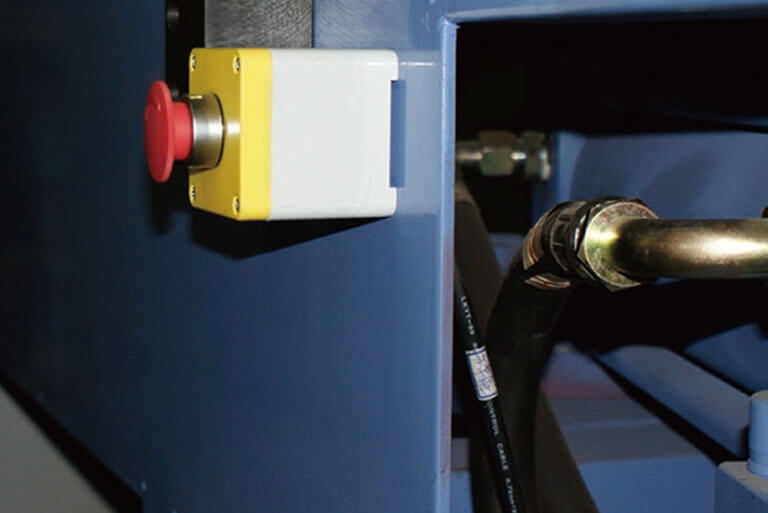

Multi-protection design

- Mobile pedal switch and side emergency stop switch keep users from dangers.

- Code protection function guards the program and process data.

- Overload protection of main motor, monitoring of mechanical, anti-unreasonable operation.

Specification

| Spec / Model | HQ-650NCAD | |

|---|---|---|

| Max. Tube O.D. & W.T. (O.D. x t) | Mild Steel (mm) | ø65.0 x 2.5t |

| Stainless Steel (mm) | ø50.8 x 1.5t | |

| Rectangle Pipe (mm) | □50 x 1.5t | |

| Max. Draw Bending Radius (mm) | 400 | |

| Max. Bending Angle (degree) | 210° | |

| Per 90° Speed/Sec | 10 | |

| Bending Accuracy | ±0.1 | |

| Max. Effective Distance of Mandrel(mm) | 2500 | |

| Horse Power | 10HP | |

| Machine Size (L x W x H)(m) | 3.6 x 1 x 1.4 mm | |

| Machine Weight (kgs) | 2300 | |

Remarks:1.Due to the continuous improvement on design, the specifications above are subject to change without notice.

2.Max. Effective Distance of Mandrel(mm) can be extended as request.

3.H-series without “Q” means “No mandrel Seat device is equipped”.