i-42 Twin

The series is a combination of cost effective and highly productive for complex work piece!

Not only having 30 tools to make it possible to process complex work piece from inside, outside and outline, it also marks the integration of the driven tools having a powerful B- axis milling for simultaneous and efficient machining. Due to this enhancement, the tools application becomes more fast and flexible for sophisticated parts. The great tool arrangement and big work area, make this outstanding, all purpose machine.

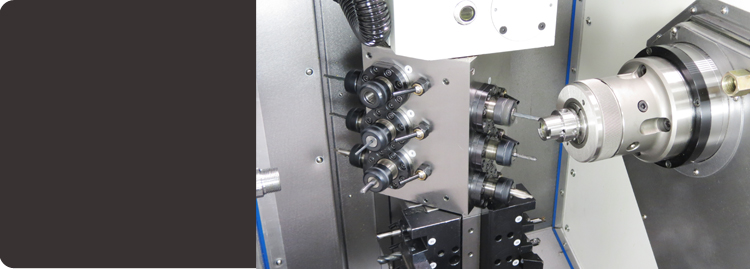

Tooling System

The flexible tooling system comes with 9 standard external tools,9 internal tools and 12 live tools. The unique tooling system can be changed easily saves every second on site. Its versatile tooling system allows complex components to be finished completely in one operation.

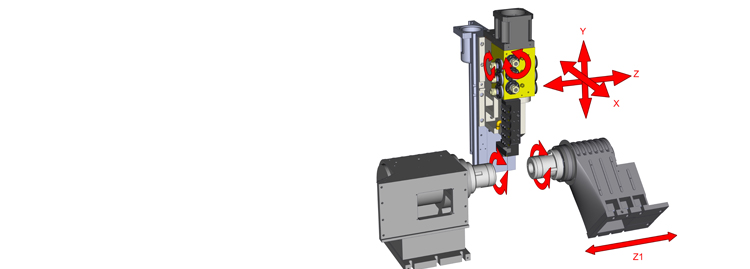

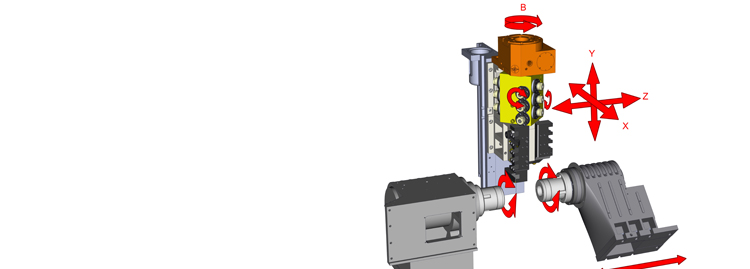

Tilting Motorized Tools-B axis

This milling head comprises of 12 motorized tools from 360° continuous leads to even greater flexible tools arrangement and significantly efficient productivity for small and medium lot sizes.

LINEAR GUIDEWAYS

The machine is equipped with high precision, HIWIN linear guideways.

The use of 35mm rails throughout the machine increases stability and accuracy, and allows heavier cuts to be achieved.

All axes are equipped with digital drives that deliver feed velocities of 20m/ min.

Specification

| Machine Type | I-42TWIN | ||

| Mitsubishi Controller | M80 | ||

|

Spindle

Capacity

|

Max. Turning Dia. | 100mm | |

| Max. Bar Working Dia. | 42mm (65mm) | ||

| Max. Turning Length | 300mm | ||

| Collet Chuck Type | KK5-173E42B (KK6-185E60B) | ||

| Spindle Nose | A2-5 (A2-6) | ||

| Spindle Bore | 43mm (66mm) | ||

| Max. RPM. | 4000rpm (6000rpm) | ||

|

Sub-spindle

Capacity

|

Max. Turning Dia. | 100mm | |

| Max. Bar Working Dia. | 30mm | ||

| Max. Turning Length | 150mm | ||

| Collet Chuck Type | KK5-173E42B | ||

| Spindle Nose | A2-5 | ||

| Spindle Bore | 31mm | ||

| Max. RPM. | 4000rpm (6000rpm) | ||

| Travel&Feed | X1/Y1/Z1 axis | 150 / 415 / 300mm | |

| X2/Y2/Z2 axis | —- / —- / 390mm | ||

| Rapid Feed | 30m/min | ||

|

Motor

|

Main-Spindle | Servo Spindle 11.0kw | |

| Sub-Spindle | Servo Spindle 3.7kw | ||

| X1/Y1/Z1 axis | AC Servo 1.0 / 1.5 / 1.5kw | ||

|

X2/Y2/Z2 axis

|

AC Servo —- / —- / 1.0kw | ||

|

Motorized Tool

|

AC Servo 1.5k | ||

|

A.T.C System

|

OD/ID Tools Main Spindle | 6 / 5 | |

| OD/ID Tools Main Spindle | 3 / 4 | ||

| Tool Shank Size | □ 20mm | ||

| Drill Holder Size (Main) | ER-20 / Ø20mm | ||

| Drill Holder Size (Sub) | ER-20 / Ø20mm | ||

| Motorized Tool | Number of Motorized Tools | 12 | |

| Max. RPM. | 4000rpm | ||

| Collet Specification | ER-20 | ||

| Max. Drilling Dia. | 12.0mm | ||

| Max. Tapping Capacity | M10xP1.5 | ||

|

Hydraulic

System

|

Hydraulic Pump / Tank Capacity | 1HP / 40L+25L | |

|

Max. Pressure / Flow

|

30 kg/cm² / 12L/min | ||

| Lubrication | Lubricant Pump / Tank Capacity | 25W / 2L | |

| Max. Pressure |

15 kg/cm²

|

||

|

Coolant

System

|

Coolant Pump | TPH4T5K, 5Bar, 75 L/min | |

| Hydraulic Pump | 2HP + SF-30C, 25Bar, 30L/min | ||

|

Coolant Tank Capacity

|

240L | ||

|

Machine

Size

|

Length/ Width/ Height | 3500 (2900) / 1900 / 1950mm | |

| Weight |

5300kg

|

||

Get Quotation Download Catalog

/home/alexpower/public_html/wp-content/themes/AlexPower/single-machines.php on line 11

/home/alexpower/public_html/wp-content/themes/AlexPower/single-machines.php on line 11