i-42 Ultimate

This innovative series stands out as an automatic lathe!

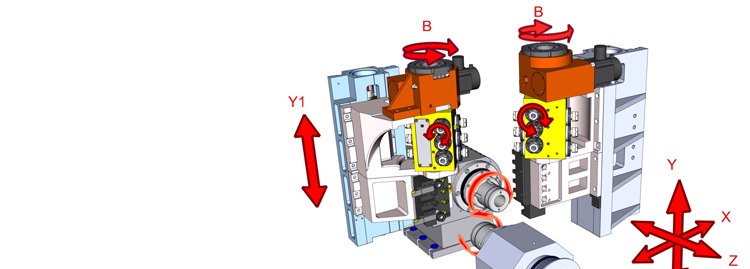

The i-42 Ultimate designation comprises of 10 axis and 4 spindles which includes a sub spindle with both X and Z positioning. This also marks the integration of the driven tools having a powerful B- axis milling for simultaneous and efficient machining. Due to this enhancement, the tools application becomes more fast and flexible for complicated parts.

HIWIN 35mm guide way C3 class ballscrew

C3 class hardened and precise ground ball screw ensure the highest precision and speed

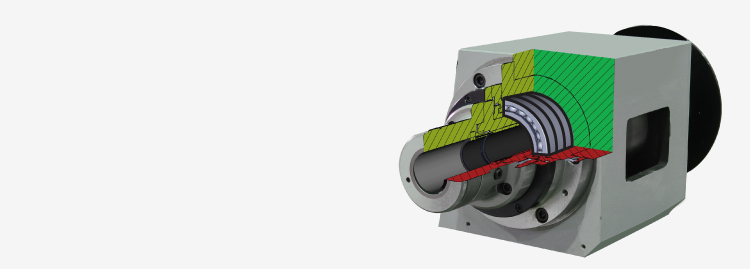

P4 class preload spindle bearing

Preload bearings are offered for the maximum attachment effect

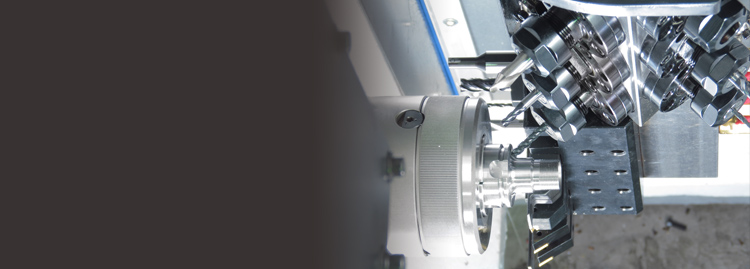

Tilting Motorized Tools

The milling head comprises of 12 motorized tools for 360°continuous leads to even greater flexible tools arrangement and significantly efficient productivity for small and medium lot sizes.

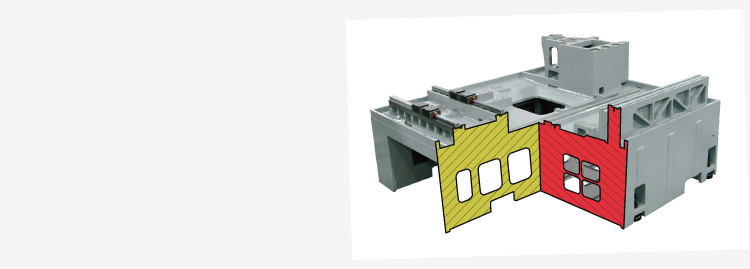

Robust FC35 Meehanite Castings

Harden to over HRB 190 and tempered to relieve stress.

SYNCHRONOUS SPINDLES

Both main and sub spindle can be synchronized for parting off operations, or can be used for turning longer work pieces.By synchronizing, transfer of the part from main to sub spindle is precise, and alignment of critical dimensions can be realized.Synchronizing can be achieved to an accuracy of 0.02 degrees while the spindles are in motion.

Dual B-axis

i-42 Ultimate

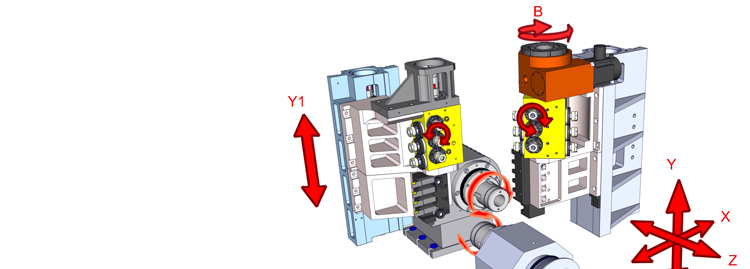

Single B-axis

i-42 Ultimate

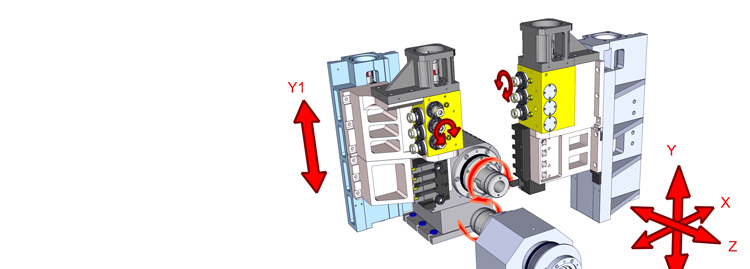

No B-axis

i-42 Ultimate

Specification

| Machine Type | I-42U | |

| Mitsubishi Controller | M830S | |

|

Spindle

Capacity

|

Max. Turning Dia. | 100mm |

| Max. Bar Working Dia. | 42mm (65mm) | |

| Max. Turning Length | 230mm | |

| Collet Chuck Type | KK5-173E42B (KK6-185E60B) | |

| Spindle Nose | A2-5 (A2-6) | |

| Spindle Bore | 43mm (66mm) | |

| Max. RPM. | 4000rpm (6000rpm) | |

|

Sub-spindle

Capacity

|

Max. Turning Dia. | 100mm |

| Max. Bar Working Dia. | 30mm | |

| Max. Turning Length | 100mm | |

| Collet Chuck Type | KK5-173E42B | |

| Spindle Nose | A2-5 | |

| Spindle Bore | 31mm | |

| Max. RPM. | 4000rpm (6000rpm) | |

| C Axis | Least Command Unit | 0.001° |

| Positioning Accuracy | 0.02° | |

| Travel&Feed | X1/Y1/Z1 axis | 150 / 410 / 250mm |

| X2/Y2/Z2 axis | 450 / 380 / 300mm | |

| Rapid Feed | 30m/min | |

| Repeated Positioning Accuracy |

0.005mm

|

|

|

Motor

|

Main-Spindle | Servo Spindle 11.0kW |

| Sub-Spindle | Servo Spindle 3.7kW | |

| X1/Y1/Z1 axis | AC Servo 1.5kW | |

|

X2/Y2/Z2 axis

|

AC Servo 1.5kW | |

|

Motorized Tool

|

AC Servo 1.5kW | |

|

A.T.C System

|

OD/ID Tools Main Spindle | 6 / 5 |

| OD/ID Tools Main Spindle | 5 / 9 | |

| Tool Shank Size | □ 20mm | |

| Drill Holder Size (Main) | ER-20 / Ø20mm | |

| Drill Holder Size (Sub) | ER-20 / Ø20mm | |

| Motorized Tool | Number of Motorized Tools | T1=12 / T2=12 |

| B axis | 360° | |

| Max. RPM. | 4000rpm | |

| Collet Specification | ER-20 | |

| Max. Drilling Dia. | 12.0mm | |

| Max. Tapping Capacity | M10xP1.5 | |

|

Hydraulic

System

|

Hydraulic Pump / Tank Capacity | 1HP / 40L+25L |

|

Max. Pressure / Flow

|

30 kg/cm² / 12L/min | |

| Lubrication | Lubricant Pump / Tank Capacity | 25W / 2L |

| Max. Pressure |

15 kg/cm²

|

|

|

Coolant

System

|

Coolant Pump | TPH4T5K, 5Bar, 75 L/min |

| Hydraulic Pump | 2HP + SF-30C, 25Bar, 30L/min | |

|

Coolant Tank Capacity

|

240L | |

|

Machine

Size

|

Length/ Width/ Height | 3500 (2900) / 1900 / 1950mm |

| Weight |

5600kg

|

|

/home/alexpower/public_html/wp-content/themes/AlexPower/single-machines.php on line 11

/home/alexpower/public_html/wp-content/themes/AlexPower/single-machines.php on line 11