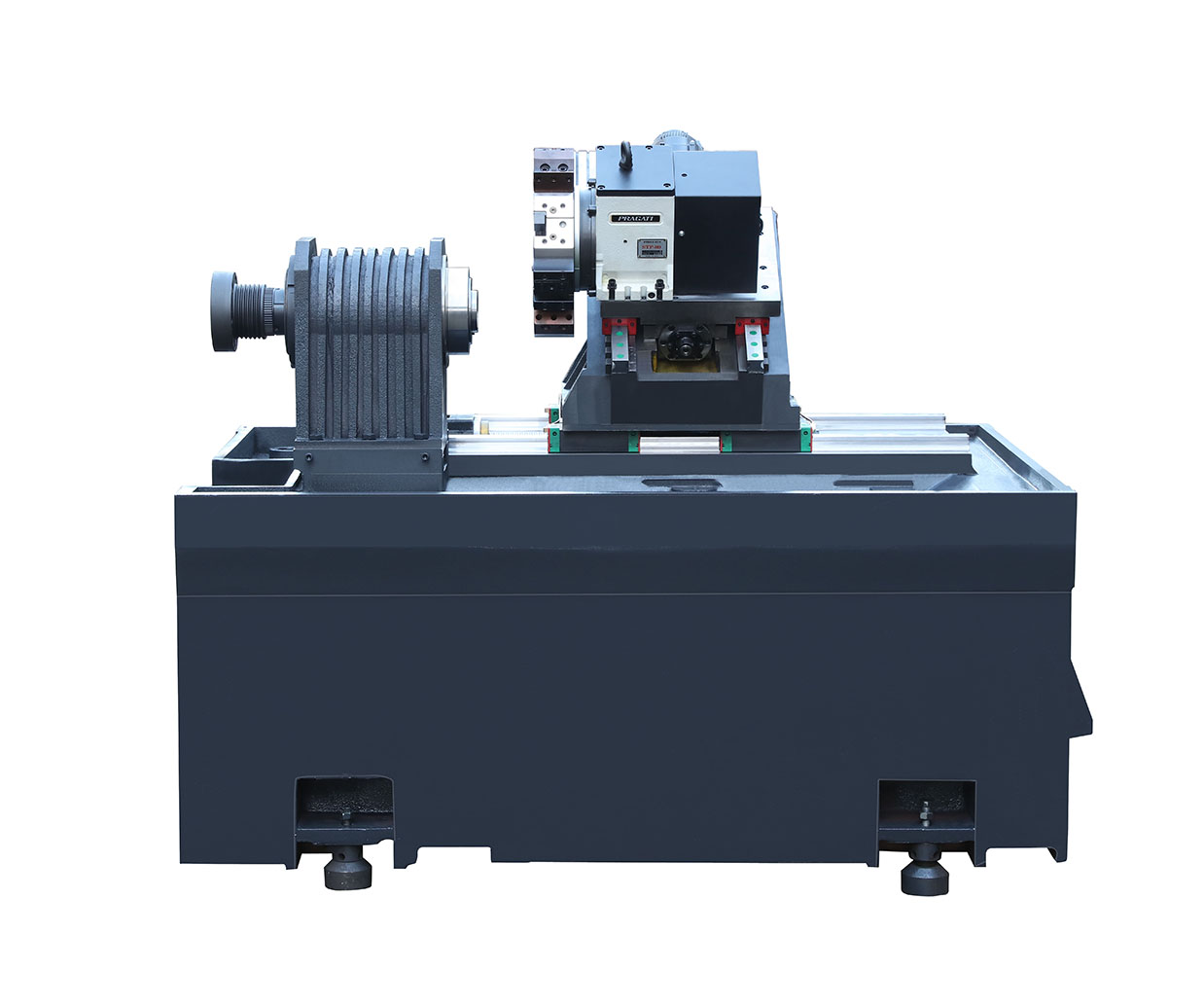

M06

High Precision CNC turning center M06 has a heavy-duty cast base with “True Align” slant bed design. The machine bed, head stock, turret and tailstock are aligned on the same plane which reduces heat build-up and results thermal expansion. The net result is a higher precision machine tool.

- Spindle runout≤2μm

- Superior spindle unit achieves high speed and accuracy

- Space saving, compact footprint

- Smooth, efficient chip removal

- Servo spindle motor, Bosch Rexroth linear guideway, THK ballscrew

SPECIFICATIONS

Capacity

- Chuck size: 6″, *8″

- Max. swing dia. over bed: Φ360mm

- Max. length of workpiece: 300mm

- Max. swing dia. over slide: Φ160mm

Spindle

- Spindle bore: Φ55mm

- Max. dia. of through-hole: Φ46mm

- Spindle nose: A2-5

- Sindle speed: 4500rpm

- Main motor power:5.5/7.5kW, *7.5/11Kw

- Spindle bore: *Φ62mm

- Max. Bar Capacity: *∅52mm

- Spindle nose: *A2-6

- Sindle speed: *4000rpm

- Main motor power:5.5/7.5kW, *7.5/11Kw

Axis

X axis travel: 160mm

Z axis travel: 320mm

X/Z axis rapid traverse: 25/25m/min

Tools

- Center height: 80mm

- No. of tool station: 8, 12*

- Tool shank size: 25×25mm

Tailstock

- Type of tailstock: Hydraulic, *LM

- Taper of tailstock quill: *MT4

- Travel of tailstock quill: *80mm

- Travel of tailstock: *80mm

Others

- Slant bed degree: 30⁰

- Guideway type: LM

- Power capacity: 13kVA

- Overall dimension: 1850×1880×1780mm

- Weight: 3000Kgs

Note: “*”means optional, “N/A”means not available.

Get Quotation Download Catalog