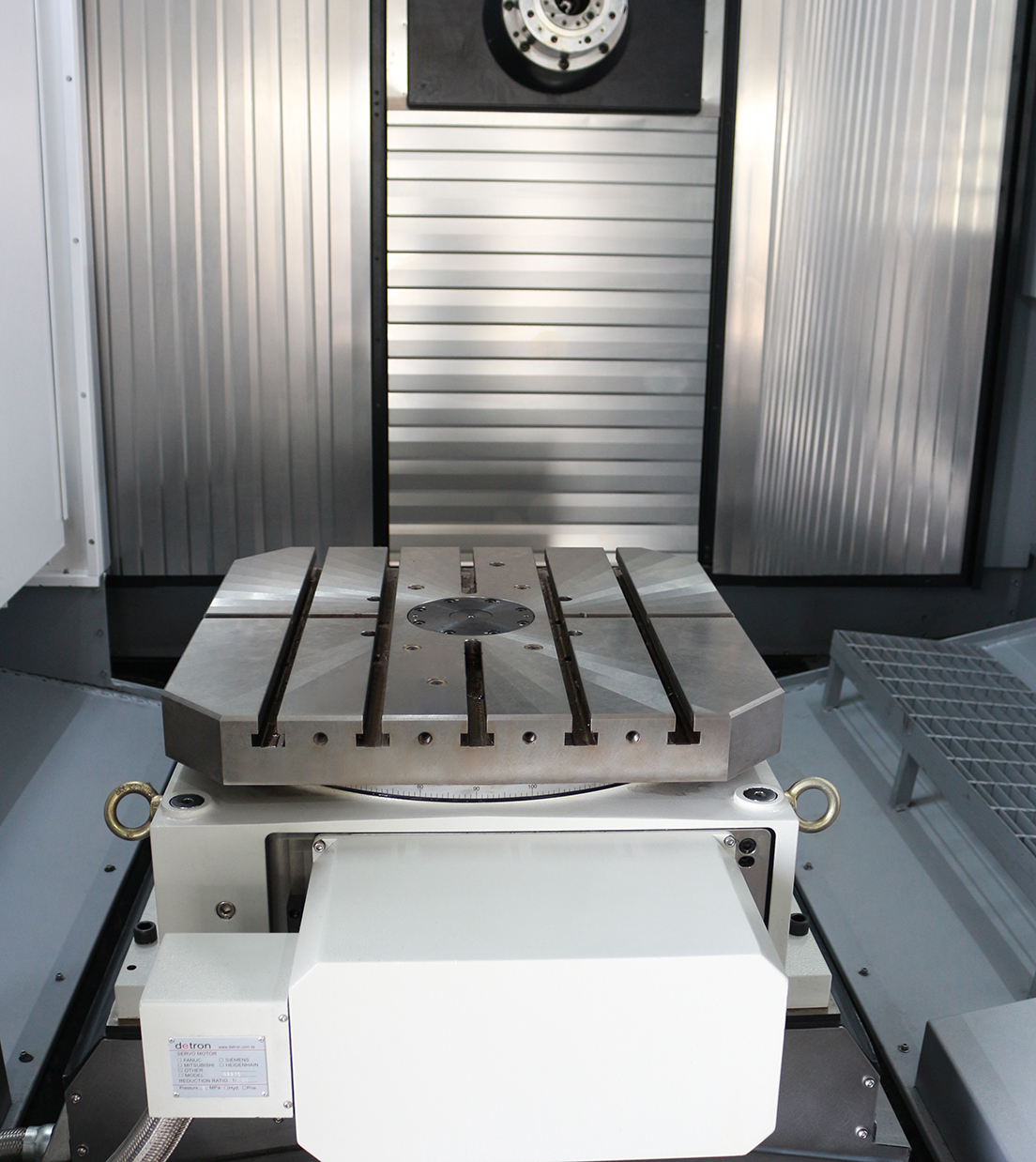

MC630H

Z-MaT’s CNC Horizontal machining centers

- Adopting finite element analysis technology, advanced Meehanite iron machine casting has been through second aging treatment, combined with optimized structure and layout, processing is reliable in long term.

- T type integrity bed structure (X axis in stairs structure) faciliates it for installation and keep accuracy.

- Standard with BT50-190 spindle and powerful servo motor, this machine has wide applications ranging from low speeds for heavy cuts to high speeds for accurcy machining.

- The three axes with bigger roller LM provide super support rigidity, which realizes excellent accuracy maintaining and smooth machining.

- Precision indexing working table gives positioning accuracy and repeated positioning accuracy on B axis. Servo motor outputs fast indexing., hydraulic lockup assures rigidity during heavy cuts on rotary table

- Preload on the three axes ballscrews minimizes the thermal deformation, increases transmission accuracy further.

SPECIFICATIONS

Table

- Table size: 630*630mm

- T slot: 18*5*100mm

- Max load: 1500Kg

Travel

- X axis travel: 1100mm

- Y axis travel: 800mm

- Z axis travel: 1100mm

Spindle

- Spindle type: BT50-190

- Spindle speed: 8000rpm

- Main servo motor: 15/ 18.5kw

Feed&Magazine

- ATC capacity type: 40/Chain

- Max weight of tool: 25Kg

Others

- Air pressure: 0.5-0.8mPa

- Electrical cabinet Cooling system:Air Conditioner

Dimension&Weight

- Overall dimension:4800x3500x3500mm

- Weight(about):16000Kg

Note: “*”means optional, “N/A”means not available.

Get Quotation Download Catalog