MiniMax 25i

Sliding Headstock Automation CNC lathe

This series offers the most efficient and cost-saving solution for mass production for 25mm complex parts, i.e medical parts, IT parts.

Tooling System

The tooling block consists of extensive 12mm turning and drilling tools. Maximum tooling capacity of 23tools allows fast chip to chip times as there is very little movement from one tool to the next.

Milling tools with a variety of configurations

In addition, to meet the demand to produce complex parts, motorized tools are also provided as optional. The standard milling head comprises of 9 live tools. Capacity is ER16 collet with 1.5 kw gear drive.

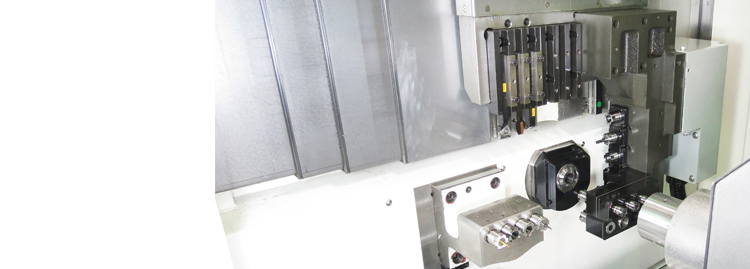

LINEAR GUIDEWAYS

The machine is equipped with high precision, HIWIN linear guideways.

The use of 25mm rails throughout the machine increases stability and accuracy, and allows heavier cuts to be achieved.

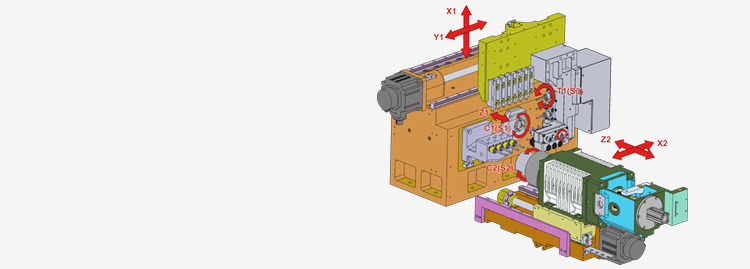

Axial view

The standard milling head comprises of 6 live tools. Capacity is ER16 collet with 0.5 kw gear drive. The head may be fitted to 8 live tools if any complex milling.

Workpiece

minimax 25i

Specification

| Machine Type | MiniMax 25i Twin | MiniMax 25i Mill | MiniMax 25i Eco | MiniMax 25i GBL | |

| Mitsubishi Controller | M80 | M80 | M80 | M80 | |

| Main spindle capacity | Max. Bar Working Dia. | 25mm | 25mm | 25mm | 25mm |

| Max. Length for Front Ejection | 100mm | 100mm | 100mm | 100mm | |

| Chuck TYPE | SR-25R | SR-25R | SR-25R | SR-25R | |

| Main Spindle Bore | 27mm | 27mm | 27mm | 27mm | |

| Max. RPM. | 8000rpm | 8000rpm | 8000rpm | 8000rpm | |

| Guide Bush | ○ | ○ | ○ | △ (option) | |

| Sub spindle capacity | Max. Bar Working Dia. | 25mm | – | – | – |

| Turning Length | 30mm | – | – | – | |

| Chuck TYPE | SR-25R | – | – | – | |

| Sub-Spindle Bore | 27mm | – | – | – | |

| Max. RPM. | 8000 rpm | – | – | _ | |

| Motor | Main Spindle / Sub Spindle | 3.7kw | 3.7kw | 3.7kw | 3.7kw |

| Axis | 1.0kw | 1.0kw | 1.0kw | 1.0kw | |

| Travel&Feed | X1 | 160mm | 160mm | 160mm | 160mm |

| Y1 | 300mm | 300mm | 300mm | 300mm | |

| Z1 | 100mm | 100mm | 100mm | 100mm | |

| X2 | 300mm | – | – | – | |

| Z2 | 230mm | – | – | – | |

| A.T.C system | OD Tools Main Spindle | 7 (□12mm) | 7 (□12mm) | 7 (□12mm) | 7 (□12mm) |

| ID Tools Main Spindle | 3 ( Ø20) | 3 ( Ø20) | 6 ( Ø20) | 6 ( Ø20) | |

| ID Tools sub-spindle | 3+4 ( Ø20mm,ER-16M) | – | – | – | |

| Motorized tool | No of Motorized Tools on main spindle | 6 (ER-16M) ( Axial x3 + Radial x3 ) | 6 (ER-16M) (Axial x3 + Radial x3) | – | – |

| No of Motorized Tools on sub- spindle | 3 (ER-11M) (Axial x3) | – | – | – | |

| Max. RPM. | 4000 rpm | 4000 rpm | – | – | |

| Motor | 1.0kw | 1.0kw | – | – | |

| Hydraulic system | Hydraulic Motor | 1HP | 1HP | 1HP | 1HP |

| Hydraulic Pressure | 50 kg/cm² | 50 kg/cm² | 50 kg/cm² | 50 kg/cm² | |

| Tank Capacity | 15L | 15L | 15L | 15L | |

| Lubrication | Lubricant Pump | 25W | 25W | 25W | 25W |

| Max. Pressure | 15 kg/cm² | 15 kg/cm² | 15 kg/cm² | 15 kg/cm² | |

| Capacity | 2 L | 2 L | 2 L | 2 L | |

| Coolant system | Hydraulic Pump | 5~7 Bar, 75L/min | 5~7 Bar, 75L/min | 5~7 Bar, 75L/min | 5~7 Bar, 75L/min |

| Coolant Tank Capacity | 110L | 110L | 110L | 110L | |

| Machine size | Length/ Width/ Height | 3100(2500)x1500x1950 | 3100(2500)x1500x1950 | 3100(2500)x1500x1950 | 3100(2500)x1500x1950 |

| Weight | 2000 kg | 2000 kg | 2000 kg | 2000 kg | |

/home/alexpower/public_html/wp-content/themes/AlexPower/single-machines.php on line 11

/home/alexpower/public_html/wp-content/themes/AlexPower/single-machines.php on line 11