NTC-2000LSY

features

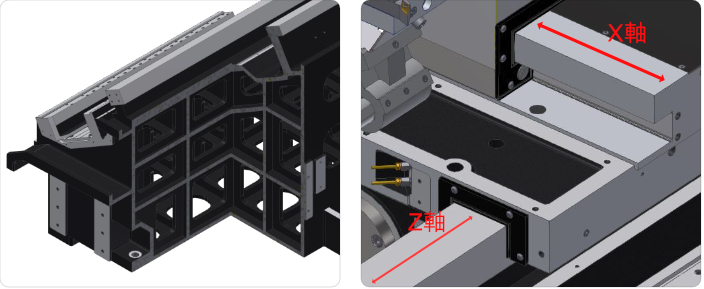

Superb Base Structure

30°One-piece Slanted Bed Design : Extends the space for chips removal.

Cross type ribs inside the base design provides the best rigidity. Durable Meehanite casting is adopted to simulate the structural deformation of the body under various conditions, integrated with YCM hand scrapping skills for box guideways, which ensures the best accuracy and lifetime. (Figure 1)

X/Z-axis boxway design with wear-resistant pad strengthens rigidity and damping capacity for reducing vibration. (Figure 2)

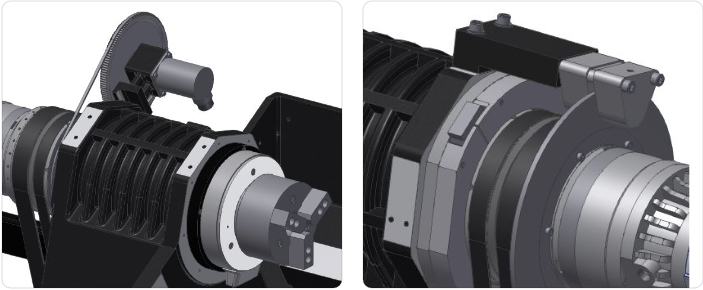

High Precision Spindle

- Hole through draw bar for bars of Ø65mm (8″) & Ø51mm (6″)

- The spindle is equipped with position encoder to detect speed and correct position. (Figure 1)

- With milling function spindle, the indexing accuracy is up to 0.001°. (Figure 2)

High Performance Y-axis Complex Machining

- Integrated Y-axis function with live tooling turret for X, Y, Z feeding, which is best for complex machining. The orthogonal Y-axis is designed for maintaining machining accuracy.

Modularized Design for Tailstock and Sub Spindle

- Except for standard manual tailstock, programmable tailstock and servo tailstock are available.

Specifications Unit : Metric

| Product Name | unit | NTC-2000LSY |

| Machining Capacity | ||

| Max. Turning Diameter | mm | Ø310 |

| Max. Turning Length | mm | 570 |

| Main Spindle | ||

| Chuck Size | 8” | |

| Spindle Nose | A2-6 | |

| Hole Through Spindle | mm | Ø80 |

| Hole Through Draw Bar | mm | Ø66 |

| Spindle Speed | rpm | 5,000 |

| Sub Spindle | ||

| Chuck Size | 6” | |

| Spindle Nose | A2-5 | |

| Hole Through Spindle | mm | Ø55 |

| Hole Through Draw Bar | mm | Ø45 |

| Spindle Speed | rpm | 6,000 |

| Travel | ||

| X-axis Travel | mm | 160(155+ 5) |

| Z-axis Travel | mm | 570 |

| Y-axis Travel | mm | 90 ( 50/-40) |

| B-axis Travel | mm | 650 |

| Feedrate | ||

| “X – axis Rapid Feedrate / Cutting Feedrate” | m/min / mm/min | 30 / 1~10,000 |

| “Z – axis Rapid Feedrate / Cutting Feedrate” | m/min / mm/min | 36 / 1~10,000 |

| “Y -axis Rapid Feedrate / Cutting Feedrate” | m/min / mm/min | 10 / 1~10,000 |

| “B -axis Rapid Feedrate / Cutting Feedrate” | m/min / mm/min | 20 / 1~10,000 |

| Motor | ||

| Main Spindle Motor | kW | 18.5/22/30 |

| Sub Spindle Motor | kW | 7.5 / 11 |

| Turret | ||

| Turret Type | Radial Power Turret (Servo Rotation, Hydraulic Clamping) | |

| Turret Capacity (opt.) | 12T(BMT55) | |

| Live Tool Motor Speed | rpm | 100~4,000 |

| Live Tool Motor Torque | kgf-m | 3.57 |

| Swing Over Turret | mm | Ø615 |

| Tailstock |

| General | ||

| Machine Weight | kg | 6,180 |

The manufacturer reserves the right to modify the design, specifications, mechanisms, etc. to improve the performance of the machine without notice. All the specifications shown above are just for reference.

Get Quotation