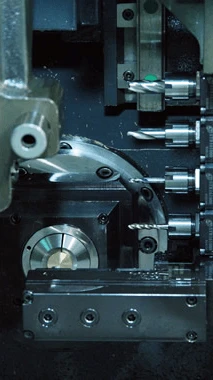

RSB-20(Y)

The Swiss type CNC lathe – RSB series has main and sub spindle and front and back tooling system, RSB-20/20Y is equipped with C1/C2 axis and X1/Y1/Z1/X2/Z2/Y2 precision axis system. The Swiss type CNC lathe – RSB series allows many kinds of tools simultaneously working on the same or different work piece to shorten the processing time. The Swiss type RSB series CNC auto lathe center is designed to allow the customer to select the appropriate configuration for given application.

FEATURES

- RSB-20 has 7 Axis simultaneously Control (X1/Y1/Z1/X2/Z2/C1/C2).

- RSB-20Y has 8 Axis simultaneously Control (X1/Y1/Z1/X2/Z2/Y2/C1/C2).

- C-axis on both, Disc brakes system, Mitsubishi built-in motor spindles on main and sub spindles.

- Guide Bush and Non-Guide Bush Design.

SPECIFICATION

| Model | RSB-20 | RSB-20Y | |||||||

| Main Spindle | Max. Machining Diameter | Ø 20 mm | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Max. Turning Length (Revolving Guide Bush) | 200 mm | ||||||||

| Max. Turning Length (Non Guide Bush) | 50 mm | ||||||||

| Min. Input Unit | 0.001 mm | ||||||||

| O. D. Tool | □12mm x 6pcs | ||||||||

| I.D. tooling | Sleeve Size | C-25-ER16 – 4pcs | |||||||

| Max. Drilling | Ø 10 mm | ||||||||

| Max. Tapping | M8 | ||||||||

| Power Driven Tool | No. of Tools | ER16 – 4pcs (Opt. 5pcs) | |||||||

| Max. Drilling | Ø 8 mm | ||||||||

| Max. Tapping | M6 | ||||||||

| Max. Milling | Ø 10 mm | ||||||||

| Power Driven Tool Motor | 1.5 kw | ||||||||

| Power Driven Tool Speed | 6,000 rpm | ||||||||

| Spindle Motor | 2.2 kw / 3.7 kw | ||||||||

| Max. Spindle Speed | 10,000 rpm | ||||||||

| Spindle Collets | 6216 | ||||||||

| Sub Spindle | Max. Machining Diameter | Ø 20 mm | |||||||

| Max. Turning length | 50 mm | ||||||||

| Back working tooling | No. of Tools | 4 pcs | 8 pcs | ||||||

| Max. Drilling | I.D. Stationary tool | Ø 10 mm | |||||||

| Power Driven Tool | Ø 8 mm | ||||||||

| Max. Tapping | I.D. Stationary tool | M8 | |||||||

| Power Driven Tool | M6 | ||||||||

| Max. Sub Spindle Speed | 10,000 rpm | ||||||||

| Sub Spindle Motor | 2.2 kw / 3.7 kw | ||||||||

| Power Driven Tool Speed | 6,000 rpm | ||||||||

| Power Driven Tool Motor | 0.75 kw | ||||||||

| Sub Spindle Collets | 6126 | ||||||||

| General | Axis Motor | 0.75 kw | |||||||

| Axis Rapid Speed | 30m/min | ||||||||

| Coolant tank capacity | 150 L | ||||||||

| Coolant Pump Motor | 0.96 kw | ||||||||

| Machine Dimension | 2450 x 1380 x 1850 mm | ||||||||

| Machine Weight (N. W.) | 3600 kg | 3700 kg | |||||||

| Power Supply | AC/3PH/220V/8~11kw | ||||||||

| CNC Controller | MITSUBISHI-M70 | ||||||||

Standard Accessories

- Revolving Guide Bush × 1

- Back Power Driven Tool (RSB-20 2pcs; RSB-20Y 4 pcs)

- Back I.D. Stationary tool (RSB-20 2pcs; RSB-20Y 4 pcs)

- Parts Conveyor

- I.D. tooling × 4

- C-Axis (Main Spindle & Sub Spindle)

- Cut Off Detector

- Power Driven Tool x4

Optional Accessories

- Power Driven Tool Unit

- Back Power Driven Tool Unit

- Non-Guide Bushing Holder

- Back I.D. Stationary tool

- 3-Spindle Front Power Driven Tool Unit

- 2-Spindle Front Power Driven Tool Unit

- Thread Whirling Tool

- Deep hole drilling tool unit

- Auto Bar Feeder Machine

- Chip Conveyor With Cart

- Long Parts Ejector Device

- Oil Mist Collector

- 70bar High pressure coolant system

- Auto Stabilizer (15KVA)

- Auto Stabilizer & Transformer (15KVA)

Design and specification are subject to change without prior notice.

The sound pressure level is 80 dB(A) at the position of one meter outside the machine.