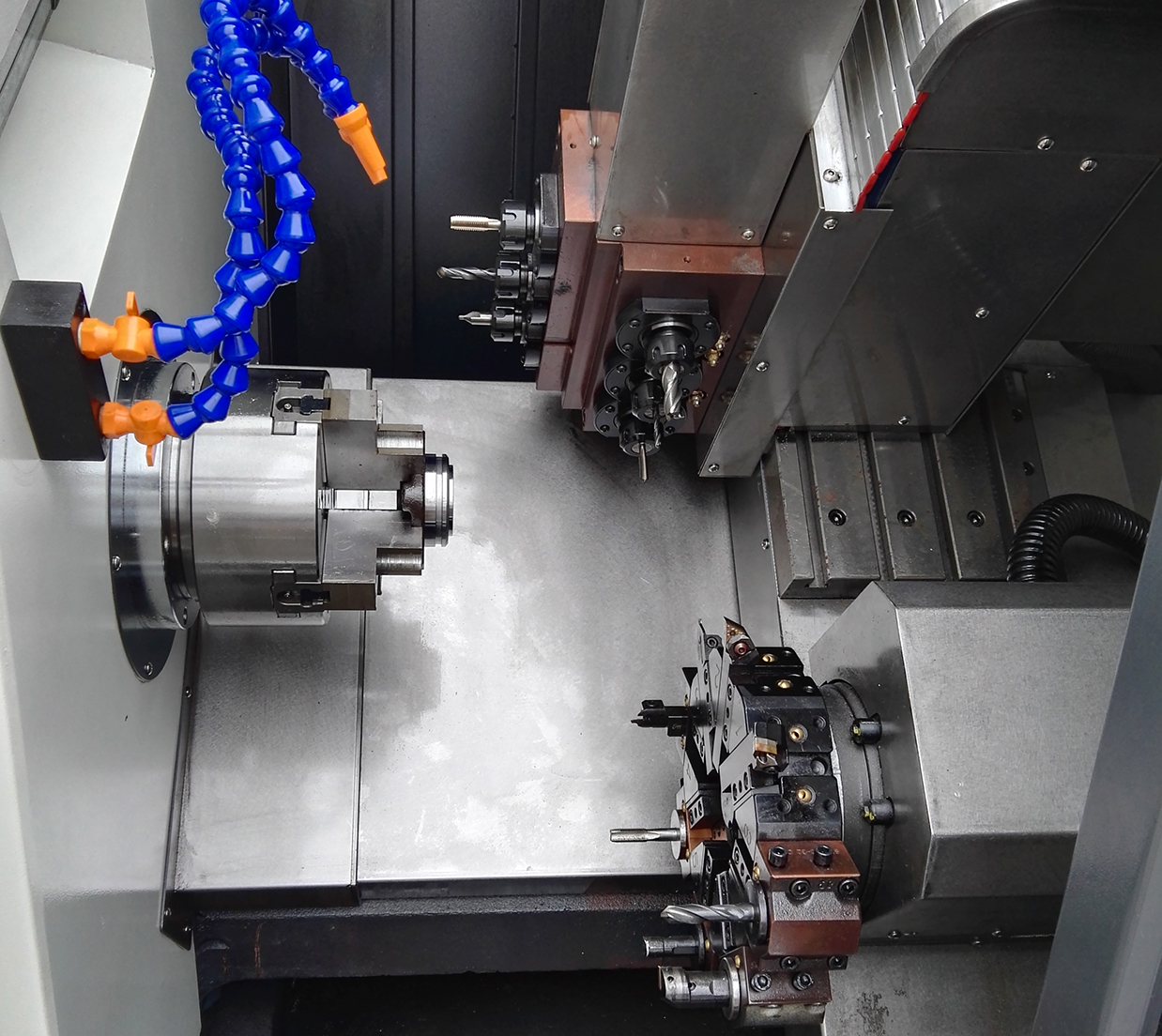

SL580-MT

580mm X Axis Travel Plus, an extra-long work table provides a large tool mounting area. This allows for a large number and variety of table mounted tooling options. This capacity makes the SL580M a powerful, “single set-up” turning center for turning, milling, tapping and drilling operations in a single part production cycle. Smart operators can combine operations into a single machining center-saving on capital input an operating costs. SL580M owners report they have gained a competitive advantage with the addition of these machines to their production system.

- Powerful Solution for Secondary Machining of Turned Parts

- Z-MaT is a recognized leader in C axis and livetooling technology. This strong core competence makes Z-MaT the go-to source for secondary machining operations.

- In addition to standard turning operations, with Z-MaT you can perform additional machining operations on a single macine-like milling, drilling, surface finishing and tapping on all surfaces. A Y axis unit is also available on many lathe models

SPECIFICATIONS

Capacity

- Chuck/ Collet: 6” Hydraulic Chuck/ Hydraulic Collet

- Max. swing over way cover: ∅380mm

- Max. Length of Workpiece: Chuck 220mm, *Collet 250mm

- Max. swing. Over slide: ∅90mm

Spindle

- Spindle Bore: Ø62mm

- Drawbar Capacity: Ø52mm

- Spindle Nose: A2-5

- Max. Spindle speed: 3000rpm, *4500rpm

- 5.5/ 7.5 kW

Axis

- X Axis Travel: 350mm

- Z Axis Travel: 250mm

- Y Axis Travel: 150mm

- X/ Y/ Z Rapid Traverse: 20/20/15 m/min

Tools

- Toolpost Type: 8-Station Turret mixed with live tooling

Tailstock

- N/ A

Others

- Bed Slant: 45°

- Guideway Type: Linear Motion

- Power Capacity:15Kva

- Overall Dimension(L ×W ×H) 2320 ×1820 ×1900mm

- Weight(about): 3600Kg

Note: “*”means optional, “N/A”means not available.

Get Quotation Download Catalog