TC-16LB

Features

High Efficiency Chip Disposal System

45°one-piece slant bed design extends chips removal space.

The independent coolant tank isolates the base from heat exposure.

A special design of the coolant tank prevents the chips from flowing into the machine.

The design of main/sub coolant tank simplifies the cleaning of chip conveyor.

The filter and sub coolant tank can be drawn out separately for easy maintenance.

High Rigidity Structure Design

- 6″ (Hole through Draw Bar ø52mm); 8″ (Hole through Draw Bar ø66mm)

With low resistance and low friction, theLinear Guideway Design on X/Z Axis prolongs machine life. - One-piece 45° Slant bed design extends the space for removing chips.

- MEEHANITE® casting with high damping capacity

- Quick and reliable servo-driven turret is hydralic clamping

- Extra large and high precision clutch provides high positioning and repeatability accuracy.

- Diverse choices of tailstock and turning length

- Diverse choices of tailstock and turning length

- High efficiency and low power loss plunger pump adopted

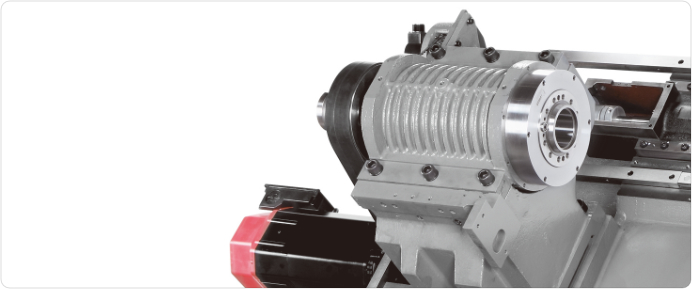

High Rigidity & High Speed Spindle

- Large diameter and high precision NN series roller bearings, equipped with angular contact ball bearings, provides the best radial and axial rigidity during machining.

- Symmetric head design dissipates heat, and reduces thermal deformation.

Easy to adjust and repair. - With low resistance and low friction, the linear guideway design on X/Z axis achieves flawless positioning accuracy.

- The axial pretension design on ball screws reduces thermal displacement.

- High Rigidity & High Speed Spindle

Automatic Production System

- Reduce manual loading/unloading time and achieve 24-hour production, improving the factory utilization.

- Save labor cost, improve productivity and lower defection rate.

- Reduce changeover time to meet the demand of low volume production of diversified parts.

- Flexible modular system and easy to be installed based on various product line.

Specification unit:Mertric

| Product Name | unit | TC-16LB |

| Machining Capacity | ||

| Max. Turning Diameter | mm | ø260 |

| Max. Turning Length | mm | 600 |

| Main spindle | ||

| Chuck Size | 8″ | |

| Spindle Nose | A2-6 | |

| Hole Through Spindle | mm | Ø77 |

| Hole Through Bar | mm | Ø66 |

| Spindle speed | rpm | 4,500 |

| Sub Spindle |

| Travel | ||

| X-axis Travel | mm | 150 (130+20) |

| Z-axis Travel | mm | 600 |

| Feedrate | ||

| X-axis Rapid Feedrate/Cutting Feedrate” | m/min / mm/min | 24 / 1~10,000 |

| Z-axis Rapid Feedrate/Cutting Feedrate” | m/min / mm/min | 30 / 1~10,000 |

| Motor | ||

| Main Spindle Motor | kW | 11 / 15 |

| Turret | ||

| Turret Type | Servo Turret (Hydraulic Clamping) | |

| Turret Capacity (opt.) | 10T | |

| Swing Over Turret | mm | ø490 |

| Tailstock | ||

| Quill Taper | MT-4 | |

| Quill Stroke | mm | 500 |

| General | ||

| Machine Weight | kg | 3,700 |

The manufacturer reserves the right to modify the design, specifications, mechanisms, etc. to improve the performance of the machine without notice. All the specifications shown above are just for reference.

Get Quotation