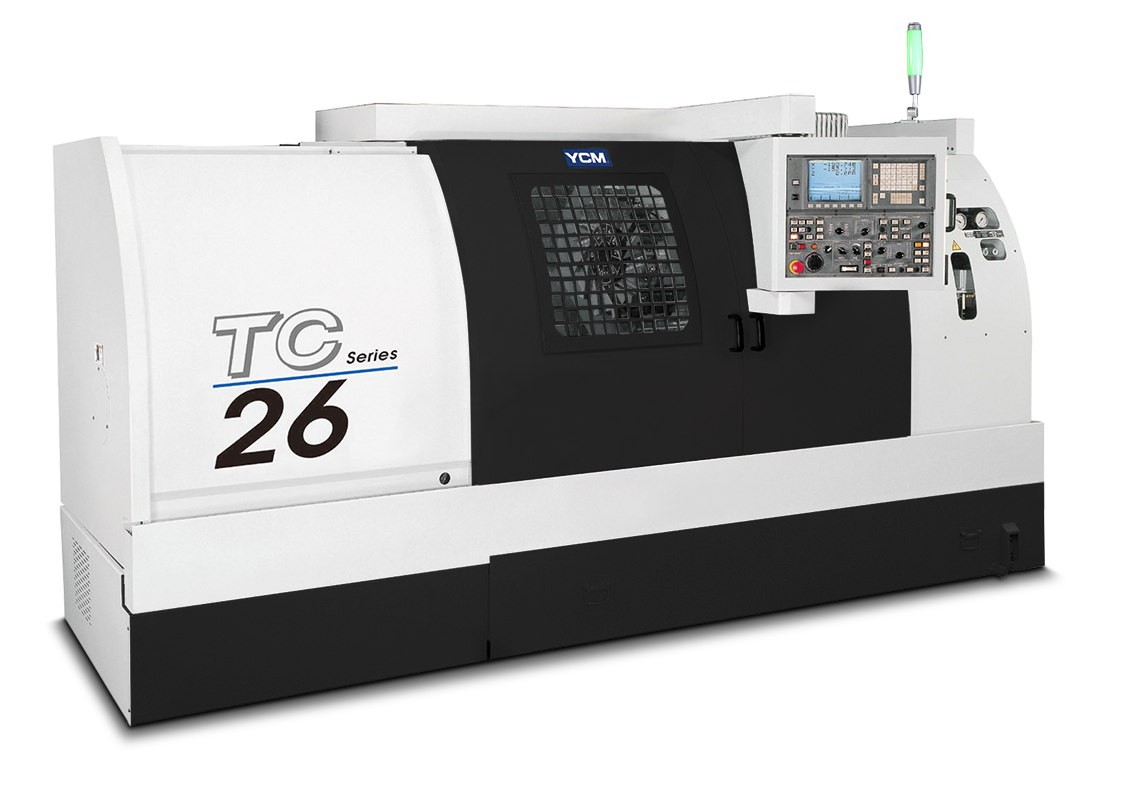

TC-26

Features

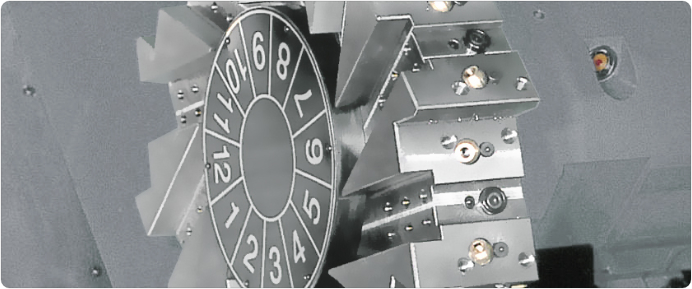

High Speed High Rigidity Turret

The 12-station turret index is done by absolute detection to reduce tool selection mistake.

The powerful turret with large diameter curvic coupling offers high precision and high rigidity in cutting performance.

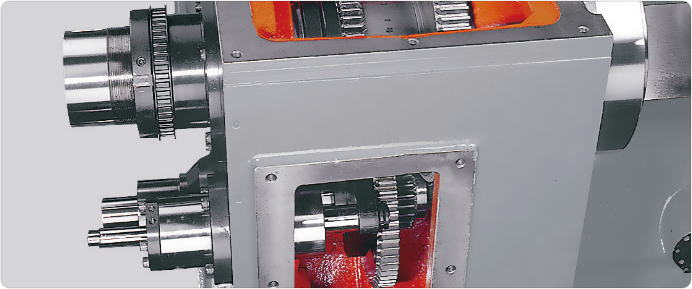

Powerful Headstock With Built-in Gears

- The spindle is equipped with high precision angular ball bearing and NN series bearing that provides high precision and rigidity working condition.

- The inner diameter of the bearing is ø120mm ø4.72″, and ø88mm ø3.46″ of the spindle through hole. ø78mm ø3.07″ of the drawbar through hole adapts large diameter bar stock jobs.

- The powerful spindle with built-in gears provides various speed transmissions. The max. output of torque reaches 74.5kgf-m 539 lb-ft, with 4,000rpm max. spindle speed.

- Material Removal Efficiency: 410cm3/min.

Insert Depth: 8mm 0.31

High Precision and High Rigidity Programmable Tailstock

- Extremely Rigid One-piece 45° Slanted Bed Design

- Using “M” code commands the quill stroke of the programmable tailstock can be hooked with a hydraulic hook to the saddle carriage and slide along the Z-axis stroke.

High Speed Ultra Smooth Axial Movement

- X/Z-axis guideways are well hardened and ground with Turcite-B to reduce the friction and offer utmost rigidity in cutting. The rapid feedrate of X/Z-axis is 15/20 m/min. 591/787ipm

User-friendly Operation and Easy Maintenance

- Hydraulic gauges, control values of chuck and tail stock, and the central lubrication system are installed at the front side; for easy adjustment and maintenance.

Directly Driven Ballscrews Of High Precision And Rigidity

- This machine is equipped with high precision ball screws and connected with motor directly.

- The fixing design supports both ends; the design of pre-tensioned ball screws provides high rigidity, high precision, and low heat effect.

Central Lubrication System

- The machine with auto-lubrication design ensures the accuracy throughout its life time.

- The slide ways of X/Z-axis and ball screws are lubricated. Built-in alarm will occurred when the lubrication oil is insufficient.

Specification unit:Metric

| Product Name | unit | TC-26B |

| Machining Capacity | ||

| Max. Turning Diameter | mm | Ø470 |

| Max. Turning Length | mm | 647 (638) |

| Main spindle | ||

| Chuck Size | 10″ (12″) | |

| Spindle Nose | A2-8 | |

| Hole Through Spindle | mm | Ø88 |

| Hole Through Bar | mm | Ø78 |

|

Spindle speed |

rpm | 10″ L: 8~195~783H: 40~1,007~4,000 12″ L: 8~195~783H: 40~1,007~2,500 |

| Sub Spindle |

| Travel | ||

| X-axis Travel | mm | 250 (235+15) |

| Z-axis Travel | mm | 700 |

| Feedrate | ||

| X-axis Rapid Feedrate/Cutting Feedrate” | m/min / mm/min | 15 / 1~5,000 |

| Z-axis Rapid Feedrate/Cutting Feedrate” | m/min / mm/min | 20 / 1~5,000 |

| Motor | ||

| Main Spindle Motor | kW | 11 / 15 |

| Turret | ||

| Turret Type | Hydraulic Turret | |

| Turret Capacity (opt.) | 12T (8T) | |

| Swing Over Turret | mm | ø640 |

| Tailstock | ||

| Quill Taper | MT-5 | |

| Quill Stroke | mm | 530 |

| General | ||

| Machine Weight | kg | 4,400 |

The manufacturer reserves the right to modify the design, specifications, mechanisms, etc. to improve the performance of the machine without notice. All the specifications shown above are just for reference.

Get Quotation