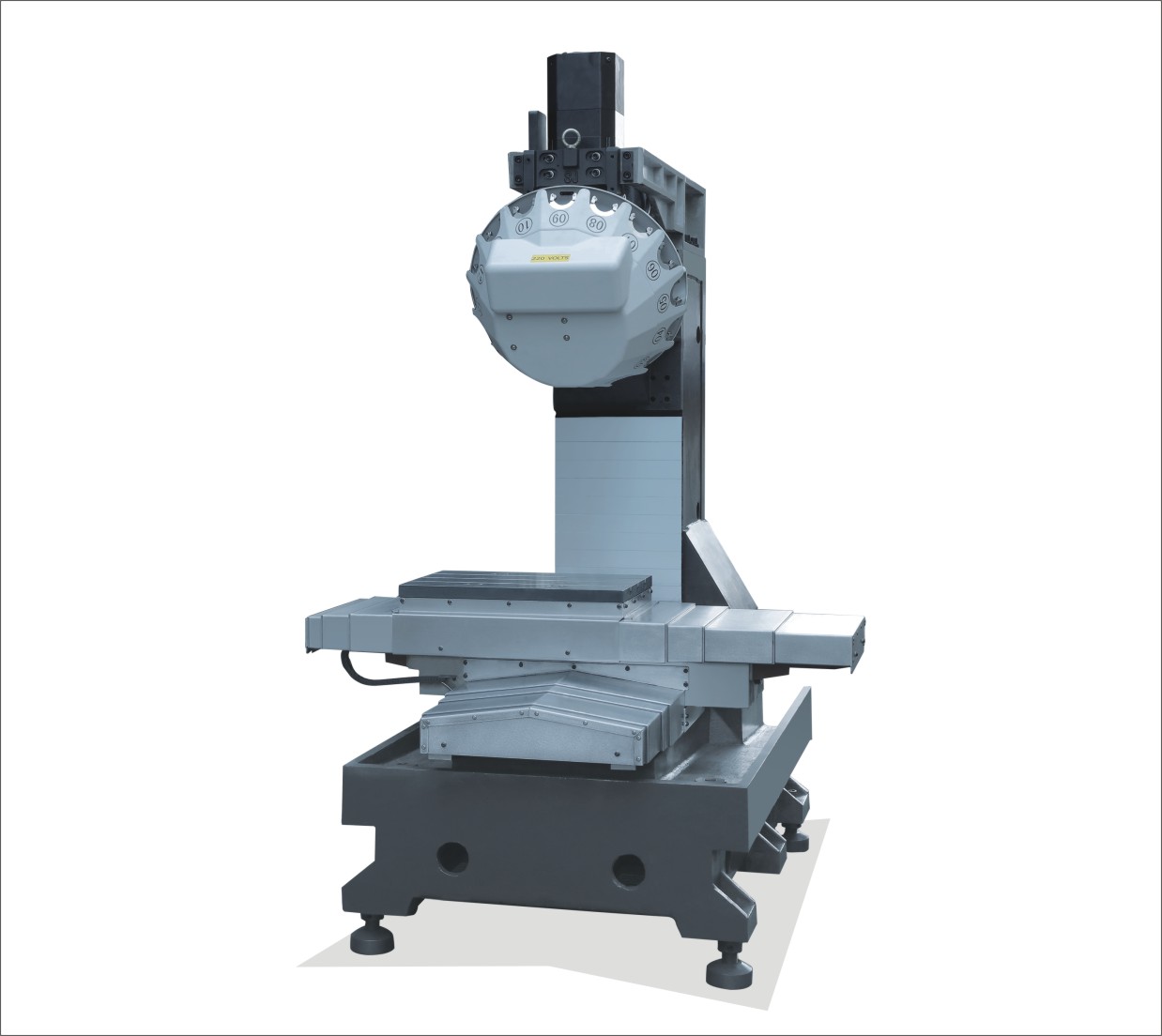

Z540

In response to customer expectations we have produced a high precision VMC tapping series with its own unique structure and upgraded performance. While the design is based on a standard, this tapping machine has our own science and engineering design ideas added into the mix. This VMC tapping center has common features that fit the unique requirements of a wide range of parts making requirements

- Advanced casting design uses precision annealing with traditional aging methods used on each casting. Provides optimal damping of vibration and ensures long-term stability and quality results.

- Both base and column have wide spacing between ways, resulting in a design that is solid as a rock and stable as a mountain.

- Direct drive spindle provides high efficiency, and low noise-assuring speed and torque during high-speed tapping operations.

- Sun type tool magazine-for rapid tool changes and solid machining performance.

- Solid ball screw, bearing structure and high precision linear guideways support rapid traverse and high speed machining. Also, assures proper orientation of machine during operation.

- Rear chip conveyor is compact and makes for easy chip removal. Chip flow is direct and easy.

SPECIFICATIONS

Table

- Table Size: 600×400mm

- Max. Table load: 250mm

- T Slot(Width×No×Distance×):14×3×100mm

Travel

- X Axis Travel: 500mm

- Y Axis Travel: 400mm

- Z Axis Travel: 300mm

- Spindle nose to table:155-455mm

- Spindle center to column: 465mm

- X/ Y/ Z axis Rapid Traverse: 48 m/min

Spindle

- Spindle Type: BT30

- Spindle driving method: Direct drive

- Spindle speed: 12000rpm

- Spindle Motor power: 3.7kW/ 5.5kW

Feed&Magazine

- ATC Type: Armless Type

- ATC Capacity: 16/ *20

- Max. Tool weight: 3 Kgs

- Tool change time: 2s

Others

- Air pressure: 0.5-0.8mPa

- Electrical cabinet cooling system: Heat exchanger, * Air Conditioner

Dimension&Weight

- Dimension(L×W×H): 1900×2100×2400mm

- Weight(about): 2600Kg

Note: “*”means optional, “N/A”means not available.

Get Quotation Download Catalog