NSV106AM

features

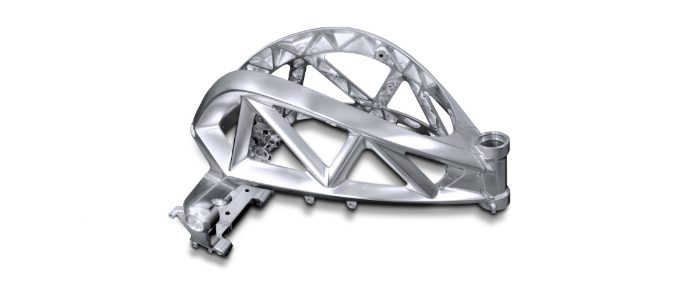

High Rigidity Structural Design

One-piece motor housing

Large delta machine column and base ensure the highest stability during high speed movement.

Advanced FEM analysis strengthens the structure while reduces the weight to provide the best cutting rigidity.

3 axes equipped with 45 mm guideways, which has a super load capacity of up to 700 kg.

X-axis equipped with 6 slide blocks increases rigidity by 50%, compared to previous model.

Y-axis guideway span with optimal ratio

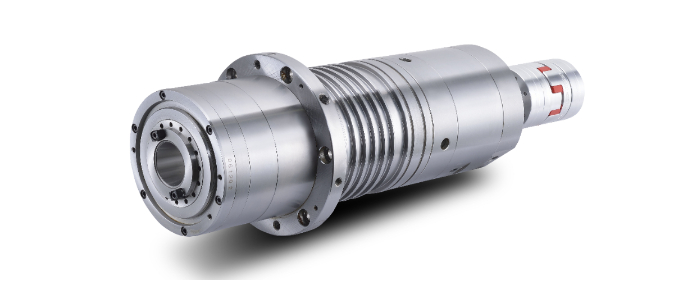

IDD PLUS Spindle Design: HIGH PRECISION HIGH SPEED

- The unique IDD spindle design offers smooth reliability at high speed.

- Ceramic bearings not just boost the spindle speed, but also achieve high axial and radial rigidity, which fulfill strict machining requirements on heavy cutting, drilling and tapping.

- Spindle cooling unit decrease thermal deformation on spindle headstock.

- Micro oil-air lubrication system minimizes thermal deformation and prolongs spindle life that are well-suited for die & mold industry.

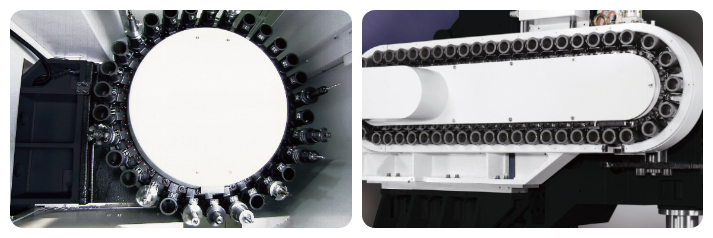

Reliable Automatic Tool Change

- Auto tool change(T-T): 1.8 sec.

- 24T Disk type as a standard

- 30T Disk type / 48T Chain type (opt.)

Efficient Chip Removal System

- Equipped with triple-chip augers as a standard.

- Dual-chip augers as an option.

High Performance Applications

- Perfect for die & mold, aerospace and automotive applications.

- Ultra-high controllability and stability.

Specifications Unit : Metric

| Product Name | unit | NSV106AM |

| Spindle | ||

| Spindle Speed (Opt.) | rpm | 12,000 (15,000) |

| Spindle Power (Opt.) | kW | 18.5 |

| Spindle Taper (Opt.) | BBT40 | |

| Travel | ||

| X-axis Travel | mm | 1,020 |

| Y-axis Travel | mm | 600 |

| Z-axis Travel | mm | 600 |

| Distance Between Spindle Nose & Table Top | mm | 100~700 |

| Table | ||

| Table Size | mm | 1,120 x 650 |

| No. T-slot x Size x Pitch | mm | 6 x 18 x 100 |

| Max. Load on Table | kg | 700 |

| Feedrate | ||

| X/Y/Z Rapid Feedrate | m/min. | 24 / 24 / 16 |

| Cutting Feedrate | mm/min. | X / Y : 1~20,000 Z : 1~16,000 |

| ATC | ||

| Tool Magazine Capacity (Opt.) | T | 24 (30/48) |

| Tool Weight | kg/pc | 6 |

| Max. Tool Dimension (W/O Adjacent Tools) | mm | ø76 x 300 ( ø125 x 300 ) |

| General | ||

| Machine Weight | kg | 7,000 |

The manufacturer reserves the right to modify the design, specifications, mechanisms, etc. to improve the performance of the machine without notice. All the specifications shown above are just for reference.

Get Quotation

/home/alexpower/public_html/wp-content/themes/AlexPower/single-machines.php on line 11

/home/alexpower/public_html/wp-content/themes/AlexPower/single-machines.php on line 11