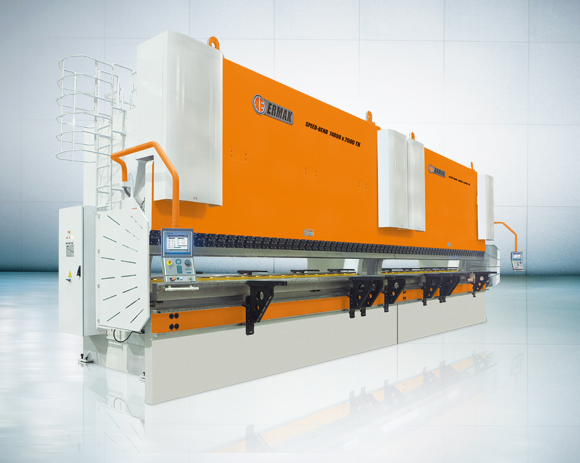

SPEED-BEND PRO

SPEED-BEND PRO Synchronized Hydraulic Press Brake

Free-fall, bending and return speeds of Speed-Bend press brakes series makes is the best choice to meet demands in today’s competitive markets. Speed-Bend series offer twice as fast production capacity compared to conventional CNC press brakes

STANDARD EQUIPMENT

- Mono block, welded steel frame rigid to deflection and high tensile with ST44 A1 material.

- 6 axes (Y1, Y2, X, R, Z1, Z2)

- Back gauge system with X, R, Z1, Z2 axis driven by AC servo with colored graphics.

- HOERBIGER servo hydraulic system.

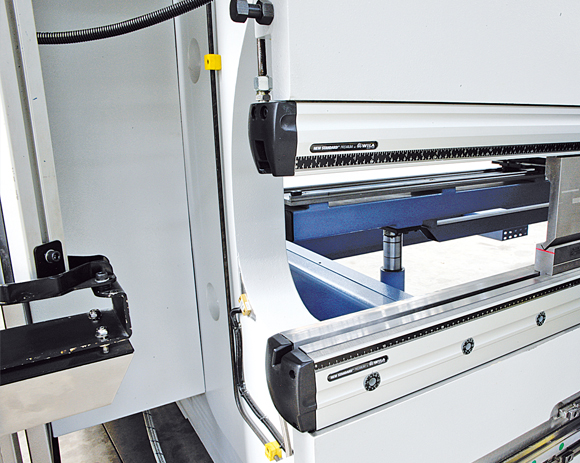

- CNC controlled motorized anti-deflection system.

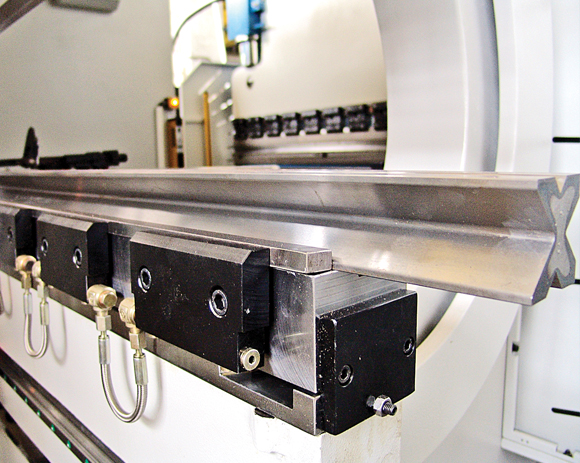

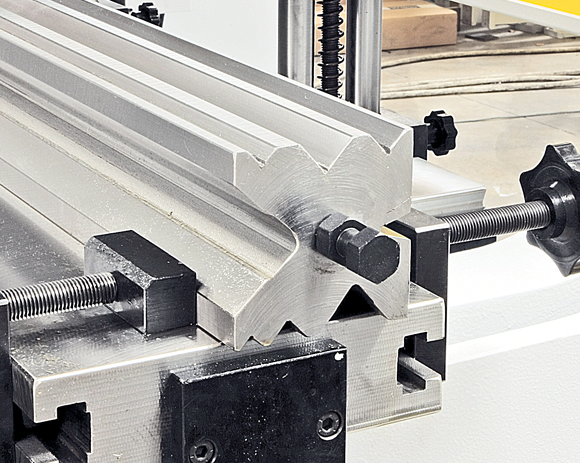

- Hardened and ground standard sectioned top and 4V-Die bottom tools (835 mm section).

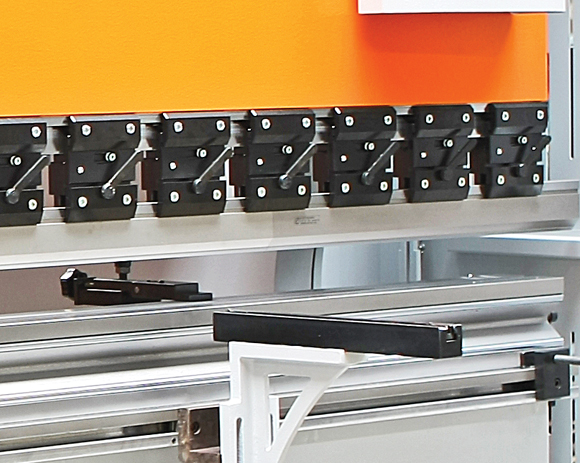

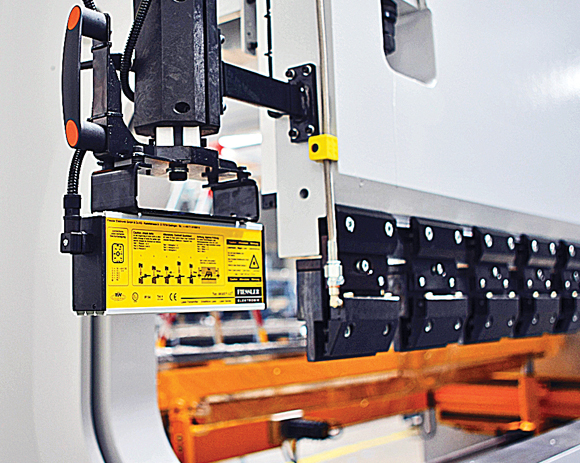

- Easy to clamp tool holding system with upper and lower tools.

- Standard graphic controllers can be selected from: ER-90 Plus 3D colour graphical touch screen controller with offline software, Cybelec ModEva 15T 3D colour graphics with PC-ModEva offline software, Delem DA-66T 2D with colored graphics.

- Electrical panel with cooling system designed to meet CE standards and composed of automation and electrical equipment with SIEMENS branding.

- Ergonomic user friendly, pendant control panel.

- Back light safety guards (category-4)

- Front side covers with safety switches.

- Synchronization of Y1+Y2 axis provided by linear encoders with 0,01 mm tolerances.

- Foot pedal suitable to CE regulation.

- Sliding front support arms with T slot and mm/inch rulers.

- Throat depth 410 mm.

OPTIONAL EQUIPMENT

- Graphical controllers; Cybelec ModEva RA Premium 3D with PC-RA Premium offline software, Delem DA-69T 3D graphical color controller with Profile T3D offline software. X1+X2 axis, R1+R2 axis.

- SICK C4000 advanced finger protections 14 mm (easy programmable Sick software with PC: Blanking, reduced resolution, cascade working etc.)

- Laser protection system for die area, LASERSAFE PCSS, AKAS LASER SAFETY IILC2000, AKAS LASER SAFETY IILC2000 (MOTORIZED), sick V 4000 (camera based system), DSP photo electric laser safety.

- Laser angle measurement system, with Data-M cobra Laser check system.

- Hydraulic and Dynamic-Hydraulic anti-deflection (crowning) features.

- ERMAK Pneumatic top tool clamping system. Hydraulic top and bottom tool clamping system.

- CNC controlled bending supports (AP3+AP4 axis).

- Hydraulic oil coolant and oil heaters.

- Automatic central lubrication system.

- Special throat depth (500,600,750 mm and above).

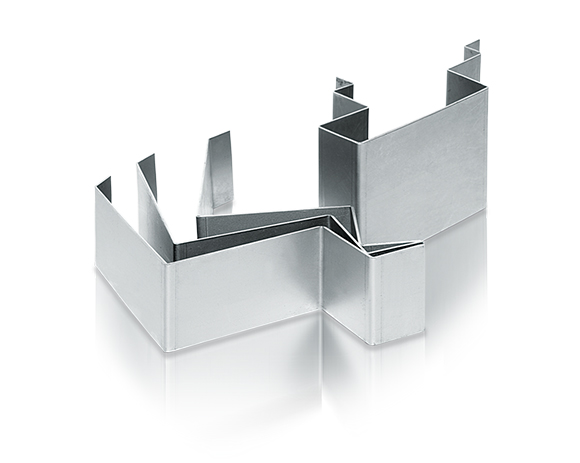

- Special top and bottom tools.

- Software options.

- Tandem applications.

- Tool cabinets.